Go offline with the Player FM app!

Crafting a Lean Culture at TaylorMade Golf With Kevin Limbach

Archived series ("Inactive feed" status)

When?

This feed was archived on September 13, 2020 23:09 (

Why? Inactive feed status. Our servers were unable to retrieve a valid podcast feed for a sustained period.

What now? You might be able to find a more up-to-date version using the search function. This series will no longer be checked for updates. If you believe this to be in error, please check if the publisher's feed link below is valid and contact support to request the feed be restored or if you have any other concerns about this.

Manage episode 209053560 series 1460675

In this episode, Tracy finds out how Renaissance man Kevin Limbach of TaylorMade Golf helped “infect the organization with great problem solvers.”

For Survey Says, we’ll find out the results of our poll addressing the biggest challenge to completing online training and certification. In the News we’ll tell you all about our tour of Zingerman’s Mail Order business (and their famous cheesecake) and for Q&A, we’ll answer a user’s question about Rapid Improvement or Kaizen Events. Great stuff!

Also Listen On: |

Timeline

- 1:58 Survey Says

- 4:46 In the News

- 10:00 Q&A

- 11:55 Coupon Code

- Special coupon code for all of our awesome listeners: 20% discount on all of our online training!

- 13:07 Today’s Special

- Interview with Kevin Limbach – Vice President, US Operations & Service, TaylorMade Golf Company

- 38:03 This Just In

- Webinar: 5 Ways to Engage Yellow Belts in Applying Their Skills After Certification

- Wonder Women of Quality: Cecilia Martinez

- Success Story: Repurposing 2,600 Hours of Transportation Waste Toward Value-add Work With Hampton Sublett

- GoLeanSixSigma.com Partners With UC San Diego Extension to Offer Green Belt Certification

Podcast Transcript

“One of the things that we learned is that if all you’re looking for is compliance, you’re not going to get sustainability. The way to get sustainability is engage the people doing the work and get commitment from them to the change and they’ll make sure it sustains and actually continue improving.” – Kevin Limbach

Tracy O’Rourke: Hi, everyone. I’m Tracy O’Rourke.

Elisabeth Swan: And I’m Elisabeth Swan.

Tracy O’Rourke: And we are from GoLeanSixSigma.com and you’re listening to the Just-In-Time Café Podcast where we bring you fabulous apps, polls, news, books, and people so you can build your problem-solving muscles.

Elisabeth Swan: Tracy, do you play golf?

Tracy O’Rourke: No. Do you?

Elisabeth Swan: No, and even though this episode has golf in the title, it’s not really about golf, is it?

Tracy O’Rourke: No, it isn’t. But wouldn’t it be cool if you could Six Sigma a golf swing? I’m sure we’d have a lot of people tuning in if we have that answer.

Elisabeth Swan: Let’s discuss it in our private dining room.

What’s on the Menu (Podcast Agenda)

Tracy O’Rourke: There is so much to talk about in this episode, Elisabeth. Tell us what we’re going to be talking about today.

Elisabeth Swan: Of course! This month, we visit the golf course or at least Tracy visits with Kevin Limbach of TaylorMade Golf to find out how they infected the organization with great problem-solvers. Those were his words. I like that.

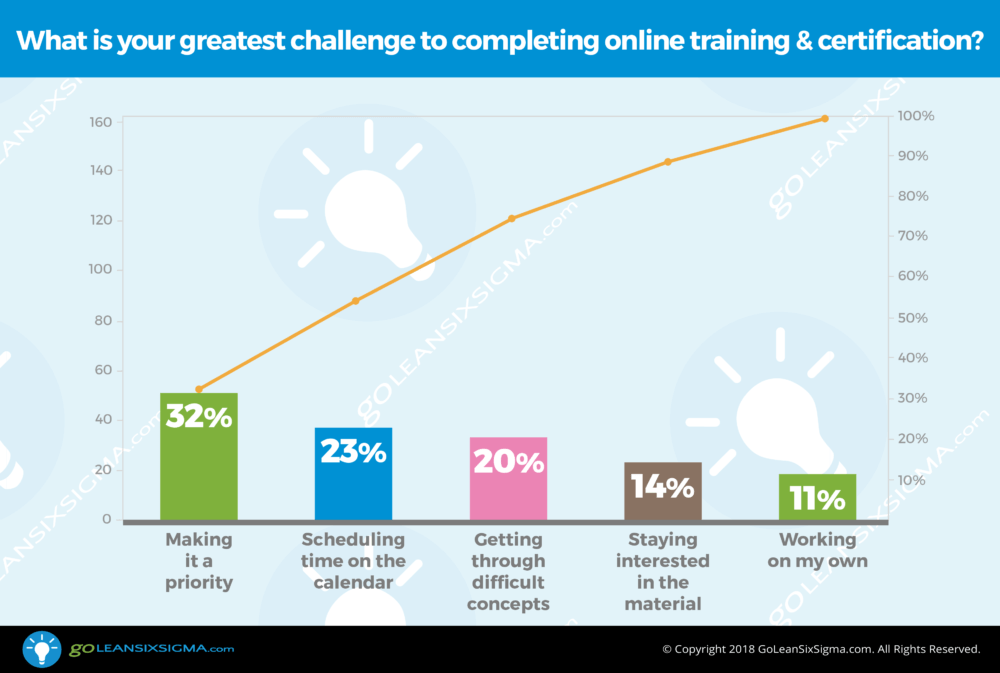

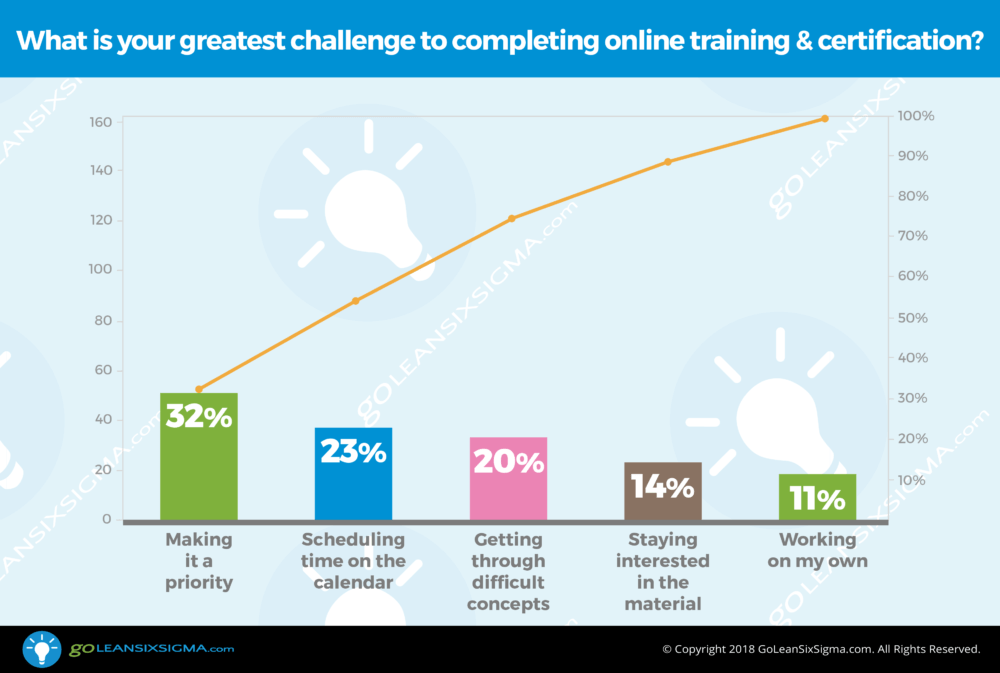

For Survey Says, we’ll find out the results of our poll question, what is the greatest challenge to completing online training and certification?

In the News, we get to tell everyone about our tour of Zingerman’s Mail Order business and their famous cheesecake.

And for Q & A, we’ll answer a user’s question about what makes a good topic for a kaizen event? I’m still focused on Zingerman’s cheesecake. But we’ll get back to that.

Tracy O’Rourke: And remember to stay tune for this month’s coupon code in order to get a discount on GoLeanSixSigma.com’s online training. Unfortunately, the discount does not apply to Zingerman’s cheesecake.

Elisabeth Swan: Bummer! Let’s get to the poll.

Survey Says

Tracy O’Rourke: I was curious about how they would answer this poll about online learning challenges. It’s not what I expected, Elisabeth.

Elisabeth Swan: You’re right. I thought the biggest challenge would be people having to learn on their own, that sense of loneliness, “I got nobody with me. I’m just me and my computer.” But that was dead last. So I was totally wrong.

So last month, we asked learners, what is your greatest challenge to completing online training and certification? And here’s what we heard:

- Making it a priority was first at 32%.

- Scheduling time on the calendar was second at 23%.

- Guiding through difficult concepts, 20%.

- Staying interested in the material, 14%.

- Working on my own, 11%.

So if you combine making it a priority and scheduling time on the calendar, that’s 55% of the challenge for people. You can see the Pareto chart on our website.

But I recently took an online course and that scheduling was key. So I put on my calendar. It was a daily repeating task. I know at 1 PM every day, I was going to spend an hour completing my course work. So that drumbeat makes a huge difference, at least to me.

So what do you think of these results, Tracy? What’s your advice for your online learners?

Tracy O’Rourke: Well, I agree with you, Elisabeth. I think carving time on your calendar to do the online training is absolutely key and more importantly, committing to it rather than saying, “Oh, I have too much stuff to do. I’m going to de-prioritize it and not do it.”

And so, we’ve been doing a lot of session, group review sessions with some of our clients and unfortunately, they ran into this very thing where they are so busy at work that they actually even have it on their calendar but then they’re not committing to doing the training when it says to do it. And they are filling it with last-minute more important things or urgent things.

So, it could be very difficult to stay committed but you’re not going to finish the training in time if there’s not commitment there.

Elisabeth Swan: Yeah, it would not happen. Take heart. Put things in your calendar and check out our new poll. We just launched it this week where we asked our listeners, who is continuous improvement coach? The options are:

- A. I have an internal coach to meet with regularly.

- B. An external coach meets with me regularly.

- C. I design my own coaching by attending webinars, et cetera.

- D. I have a coach but I never see or meet with them.

- E. I don’t have a coach and I wish I did.

Go ahead and take that poll and we’ll discuss the results next month. I’m Elisabeth Swan and you’re listening to the Just-In-Time Café Podcast. We love your feedback. Please leave a review on iTunes or our website and don’t forget to subscribe!

Tracy O’Rourke: Cool. Up next, it’s In the News.

In the News

Tracy O’Rourke: OK. One of my most favorite things to do with my job is to actually take tours of organizations that are implementing and Lean and Six Sigma. And this was such a revelation, really fun. Where do we start, Elisabeth?

Elisabeth Swan: I don’t even know. Tracy and I as Tracy said, I haven’t done as many as she has but now, I’m hooked. So we took a tour of Zingerman’s Mail Order business in Ann Arbor and my eyes were popping. My ears were popping.

Tracy O’Rourke: Yes. So we have the pleasure as Elisabeth just said of attending this workshop with Jeff Liker and Karyn Ross. And as part of this workshop, we got to tour two organizations, Menlo Innovations which is a software company and Zingerman’s. And both of these organizations are highlighted by the way in their book, The Toyota Way to Service Excellence. So I was really looking forward to visiting both of these organizations because I had already read about them in the book.

And so, I really wanted to see what these organizations were doing. And boy, that was such a great experience. If you were looking for an excellent example of just using takt time, you should go to Zingerman’s. They have that dialed. And it’s crazy how they’ve been able to scale their business to meet customer demand for the holidays because it – what is it? Like it goes tenfold during the holidays or something crazy.

Elisabeth Swan: It gets crazy, yeah. We’ll talk about the other stress that it put on their processes to have – most of their business happen during the holidays. Yeah, they had printer that takt time things well. The printer was printing orders based on takt time. So people would just pull and pick and pack. So those were great.

The other thing that struck me was I love the story that Chief Operating Officer Tom Root told about completely altering their hiring practice.

Tracy O’Rourke: Yeah, that was pretty innovative.

Elisabeth Swan: Yeah. And I think that came out of what you just said. They do most of their business during the holidays. So they have to ramp up their temporary staff by 500 people. It’s crazy. And you and I were there. It’s a warehouse. It’s not a huge warehouse. I’ve seen a lot bigger. But they would have lines out the door and down the street. And this is getting into the holiday season. It’s Michigan. So it’s not nice outside. People were wrapping around the blocks.

And then they had really tired interviewers, people that are talking to thousands of people and getting really tired. So those of you who have ever had the job of interviewing new hires, it’s already a crap-shoot. So the process just ended up being in their case, run by bias.

I think Tom said when they looked at some of those applications, they had 2,000 applications to sift through after this day of interviewing. And most of them, just – the interviewers said, “Nice. Seemed friendly.” So hiring was just based on assumptions. They sat down. They said, “Hey, we’re using this Lean stuff, why don’t we try creating a future state value stream map? Let’s see if we could invent a process that’s better than what we’ve got.”

So, the new process that they designed said they would only take 25 people at a time and they would schedule those 25, each time, for a 30-minute reservation window. So people were not lining up around the block. They knew exactly when they had to be there. They would show up. Name tent was at the desk. They were given a sheet and that was their scorecard.

Then each candidate worked through a series of skills test. They put them right on the job. They tested them by having them do some of the tasks that they’d be doing if they got the job. And if they failed any of the tasks then they’d be taken to a secluded spot and let down carefully and then let out what they called the “No Door.” And he said, “So if they weren’t happy, it’s OK. They’re in a private space.” They can have their emotional moment.

But if they succeed in all the skill tests, then they – everyone claps and cheers and they say, “You’re hired!” since that’s all that mattered. And as long as they can do the work in the 5 remaining then people filled out a job application, which is so it’s after the fact. That’s genius. So there’s no need for those other 1,500 job applications or people they weren’t going to hire. They told them their shift, their first day, and what they’d be doing. End of interview. Hired. Applied. Done.

So they designed that ideal state map and then they built the new process. And it took them a while to perfect it but they fundamentally transformed their hiring process and it’s just really cool.

Tracy O’Rourke: Yeah. I am really impressed with that. That is so cool that they really transformed how they hire people and they applied Lean, which is super cool.

Elisabeth Swan: Yeah. And you can check out a little visual that we took when we were there. You can check out the Lean Six Sigma Everywhere blog for a photo of Zingerman’s Weekender Shadow Boards, one of their most popular gift boxes because it has that cheesecake. But it’s really cool. It’s just a piece of cardboard, right? But they had of course the glossy image of the cheesecake. So yeah, we got hungry.

Tracy O’Rourke: Yup. And if you guys want to send us a gift basket over the holidays, I’d be glad to accept one.

Elisabeth Swan: Happy to accept those. Happy to.

Tracy O’Rourke: I’m Tracy O’Rourke and you’re listening to the Just-In-Time Café Podcast. In a short while, we’ll get to hear my interview with Kevin Limbach, Vice-President of US Operations and Service at TaylorMade Golf.

Next up, it’s a question from our listeners.

Q & A

Elisabeth Swan: So Tracy, you took this question about kaizen events which is the Japanese term for a rapid improvement event, right?

Tracy O’Rourke: Yes. So we had a learner who asked, “What are some good examples of Kaizen events or rapid improvement events?” And really, that’s what a kaizen event is. It’s typically a 2 to 5-day event that a team of people are sequestered to actually get some work done. The specific work is dependent on what the agenda entails.

And the best kinds of kaizen events are the ones that obviously get results. But there are a lot of different kinds of agendas that kaizen events have. You could conduct a process walk and build a value stream map and some people call that a kaizen event or there might be other very specific things like doing 5S or workplace organization or developing visual management.

It’s really important to have it well-laid out with solid goals and objectives and activities that are going to meet those goals, help the team reach those goals.

There have been other events that are even more complicated, developing work sales or poll systems or designing single piece flow for manufacturing floor or plant or product. So, there are lots of things that can happen but I think the big challenge I see is people underestimate the planning of a kaizen event. It’s really important to have it well-laid out with solid goals and objectives and activities that are going to meet those goals, help the team reach those goals.

So if a kaizen event is not successful, here’s the issue. People on your organization are going to be less likely to attend one in the future. So do your due diligence. Don’t waste people’s time. Make sure it’s providing value.

And if you are going to be doing kaizen events regularly, I’d highly recommend buying the book, The Kaizen Event Planner. It’s by our friends, Karen Martin and Mike Osterling. It’s very thorough, very comprehensive, and it will help make your kaizen events successful.

Elisabeth Swan: Great book. I recommend it too. Coming up next, it’s Today’s Special. Tracy, give us a little preview of your interview with Kevin Limbach.

Tracy O’Rourke: Yes. I really had the pleasure of speaking with Kevin Limbach. He is doing so much work at TaylorMade Golf and really making a difference. But he is also donating his time to nonprofits and helping them along the Lean journey as well. So he’ll talk about that as well as some of the trials and tribulations that TaylorMade Golf has encountered on their journey.

So if you want to hear the voice of a leader and how Lean has transformed how they operate, stay tune.

Today’s Special

Tracy O’Rourke: Hi, everyone! Welcome. You’re listening to the Just-In-Time Café. I’m Tracy O’Rourke. And joining me today is Kevin Limbach, Vice-President of US Operations and Service at TaylorMade Golf company. How are you today, Kevin.

Kevin Limbach: Oh, I’m doing great. How are you, Tracy?

Tracy O’Rourke: I’m wonderful. Thanks for coming to the café to share some of your experiences as a leader in process improvement at TaylorMade. So before we get started, let me tell you a little bit about Kevin.

Kevin Limbach’s early career was spent in the printing industry. And since then, he has held various positions in the golf equipment industry over the last 20 years, most recently as VP. He is an active practitioner and proponent of Lean thinking and currently serves on the advisory board of the San Diego State University’s Certification in Lean Enterprise Program.

He is also a graduate of George Mason University and holds professional coaching certifications from the Hudson Institute of Santa Barbara and the International Coach Federation.

He also serves on the advisory board for the Global Supply Chain Management Department at Cal State University San Marcos and on the board of directors at Feeding San Diego.

Welcome, Kevin. You are very active.

Kevin Limbach: Oh yes. Well, I don’t have any trouble staying busy. So thanks for that. That sounded a lot busier than it actually seems.

Tracy O’Rourke: Well, good. So I’m really excited to talk with you. TaylorMade Golf has been on a Lean journey for a while and I’d love to hear a little bit about your experience and a little bit of history of what has been happening at TaylorMade. Would that be OK?

Kevin Limbach: Sure. Absolutely. So, I can give you kind of the rundown of the Lean journey since I came to TaylorMade back in 2006.

Tracy O’Rourke: OK.

Kevin Limbach: So I came with some experience. I had worked at a previous position with some folks who had worked at Toyota. So I learned a little bit about problem-solving and A3 thinking and strategy deployment and problem-solving from them.

And when I came to TaylorMade, there was a pretty active segment of the company involved. They had just done kind of a major transformation from batch processing to cellular flow in the club assembly operation here in Carlsbad. Very well done. Very effective. But that was kind of the extent of it. So not much involvement by the folks in operations at large.

I kind of took some of the experience I had had. Started doing some kaizen events in our warehouse, in our club assembly group and it really got a lot of good response from the folks in the floor, which is what you typically see, right? The people on the floor are dying for this kind of engagement and attention.

And through some of that, some of the report outs that we did, we got the attention of upper management and got the encouragement to go a little bit broader with the efforts.

So the next thing is, we started taking groups of people through the San Diego State Certification and Lean Enterprise Program. We started with about five people and then it was five more people.

So in 2007 and 2008, there were groups going through this, each working on these really effective projects. A lot of them not kind of manufacturing projects. A lot of them were administrative type efforts. And that also got the attention of people here and kind of spurred the effort on.

At any rate, after we had sent about four or five groups through the public program, we decided to bring the training in-house. And I think for two, maybe three years, we were putting 50 people a year through the program here on site. And some of the results of that were very eye-opening for everyone in terms not only the tangible results but the level of engagement and kind of driving the leadership.

We had a kind of a company initiative in time called Distributed Leadership. And this really fit nicely with that. It was a vehicle for that. So at one point, we had gotten so far down the road with this training that we had trained 150 out of the 600 people on campus in this program. And everybody was very enthusiastic about it and the results were great and kind of the environment here at TaylorMade was very competitive. So, these teams were competing with each other and they were kind of over the top in their presentations and it was just – it was really, really fun and impactful at the same time.

And we had a group here that was kind of the gatekeepers or the kind of steering committee I guess you’d say for the Lean involvement at the company. And we got in a room one day and looked around each other and said, “Well, we’ve got 150 people through this program. What kind of support might they need from us to keep taking what they’ve learned and then keep applying it here at the company?”

We decided to get the groups together in small teams, the teams that went through the program together and just ask them. What have you been able to do with what you learned in the training and how come we help you?

And this was another kind of milestone or a Lean journey because when we talked to folks, what we heard was, “Hey, you know what? I was so grateful that I’ve had the opportunity to learn about Lean thinking. I will never look at my job or the world the same way again.” I mean it really teaches you to look at things differently and identify ways, the non-value added processes and really think differently about what we do. But I really haven’t found anything to do with it back on the job.

Tracy O’Rourke: Darn it!

Kevin Limbach: Yeah. Kind of waiting for somebody to give me my next big project. So that was a pretty consistent theme. And so, we got back together and said, “Well, uh-uh. If we were thinking that we were giving people skills and tools to take back to the – where they work and start making improvements, it’s not panning out that way.”

So what we decided to do with that is to focus on PDCA as the tool that we would use to give people – to kind of build on the overview training that they got in the San Diego State Program but to give them some more specific problem-solving capability through doing PDCA, the 8-step problem-solving method, the kind of A3 problem-solving method.

So we were fortunate enough at the time to have hired somebody who had worked at Toyota and really was able to teach us what PDCA really meant and how it really was to be applied. So we developed and we worked with the Lean Enterprise Institute and there’s kind of an offshoot called Honsha that Sammy Obara is affiliated with.

Tracy O’Rourke: Yup. I know Sammy. He lives in Vista. He is a local.

Kevin Limbach: Yeah. Sammy is fantastic. Anyway, so they helped us developed this kind of advanced problem-solving training and we went into it with kind of the philosophy of infecting the company with great problem-solvers. We were going to take people who had shown capability and commitment and kind of the aptitude out of the classes and put them through this advanced training in problem-solving.

So, we started doing that and it really paid off big time for us. Through that, we were able to kind of develop a cadre of about half a dozen people who are skilled in A3 thinking and PDCA problem-solving. And about this time, the company hit a rough patch on the industry took a downturn. We had some profitability issues.

And here, we were as kind of the Lean group, showing up with people who were able and willing to dive into the business problems that we had. And that’s how we focused their efforts and it paid off really big time. It was – we were in exactly the right place with that at exactly the right time as far as the company went.

Tracy O’Rourke: Well, the good news is, it sounds to me like you got a head of the curve. You spent a lot of time training people, getting people excited, having some success with projects, and you didn’t wait until the downturn happened it sounds like. And so when the downturn did happen, you guys were ready really to handle those kinds of bigger issues it sounds like.

Kevin Limbach: Yeah. And that’s a good point. And then let me back up a little bit because there’s a missing piece of the story here that factors into that. Along the time that we had gotten on some tension in the company from kind of the executive team in the company and the CEO of the company, he was very – the CEO at the time was very impressed with the level of engagement and the results he was seeing from the teams that were going through the San Diego State training and said, “Oh, we got to do this for everybody. We got to get the entire company trained on this.”

So we took a run at strategy deployment with the executive team and it was a plane crash. I would have to say.

Tracy O’Rourke: How come?

Kevin Limbach: Trying to take the culture like a sales culture and adapt it to kind of what they viewed as a very process-driven kind of engineering cut and dry strategy deployment process. It just didn’t go. I mean the kind of the organism spit that out.

And so, we had kind of as the group that was leading the Lean effort here, we had to kind of pick ourselves up and dust ourselves off and said, “OK. Look, that didn’t work. So we should just keep doing the right things and keep moving ahead and sooner or later, the business will come back around to us.” And that’s what we did.

So we decided that problem-solving was the right focus. We developed our own kind of limited strategy deployment or Hoshin process to decide where we would focus the problem-solving to get the impact to the higher business goals. And sure enough, the business did come back around and we were in the right place.

There is going to be resistance. There are going to be setbacks. And you just need to keep your eyes on the prize and keep going forward.

So the moral of that story for me is you know what the right things to do are, if you’re a believer, you have to keep believing and you know what the right things to do are and just keep doing the right things and keep moving forward because there are going to be bumps along the way. There is going to be resistance. There are going to be setbacks. And you just need to keep your eyes on the prize and keep going forward.

Tracy O’Rourke: And culturally, you probably learned something because again, these tools work. Lean works. The philosophy works. But it’s really finding what works at TaylorMade or what works at any organization because the deployment of it does look a little different no matter where you go.

Now, you had mentioned earlier that one of the challenges you ran into was that people were sort of waiting around for this, “Where is my next big project?” And so, you incorporated PDCA with the help of Sammy, which I love him too. He is awesome.

So, I wanted to ask you, did that actually help people to constantly apply the process improvement thinking and methodology by implementing some of that? Because you were really – it sounded to me like you really wanted to close that gap of why are people waiting to be told what to work on?

Did the PDCA approach help close the gap so that they were sort of self-starting on their own with process improvement?

Kevin Limbach: Yeah, that’s a great question. And I would say that no, it didn’t for the whole group of people who had gone through it because one of the other things that we learned is as kind of simple as the concepts of PDCA are, it’s very difficult. Very difficult. Much more difficult than you could possibly imagine to train people to really get it. And it’s just so counterintuitive but that’s exactly what we found.

So, the kind of the success rate even with kind of the down selected folks that we put through the advanced training wasn’t one hundred. So it was very difficult.

So not only was it difficult, another thing that we learned is that it requires hands-on, one-on-one coaching to really help people get it and be effective with it. So it’s a pretty big time commitment to evoke the resources to do the training, to carve out the time for people to work on their PDCAs but more importantly, to have someone, a coach, coaching them through this. So think about this as the managing to learn kind of paradigm and have the person working the A3 and then someone coaching them through that.

So what we found is that – our experience was that even with really capable folks, it took a couple of iterations of a coaching through A3s before they were independent. And actually, some people never got there for a variety of reasons. Some of them is kind of mundane as they couldn’t find the time within their jobs to do the work. So …

Tracy O’Rourke: So you’ve been doing this now since 2006 TaylorMade got started and you’ve been there for that. What would you say as a Lean leader, what would you say are some of the key principles that you believe or that you’ve embraced to make this effective in your organization?

Kevin Limbach: Well, I would say the number one thing that I’ve learned is that there’s really no difference between Lean leadership and leadership. So the attributes or the behaviors, the thinking that makes a good leader a good leader and an effective leader are the same things that make a Lean leader a good Lean leader.

And what I mean by that is it’s not as difficult to instill and teach people the technical part of Lean, the concepts, the nuts and bolts, the methods, that kind of stuff. What’s really hard is kind of the adaptive training that you need, the adaptive behaviors.

Now, what are you going to do when you’re responsible for making a transformation in an area and getting people to go along? They’ve been doing things the way they’ve been doing them for years. You don’t have any direct responsibility over them. It’s all through influence. How do you going to deal with the resistance? How are you going to get people to engage in the work and you get commitment instead of just trying to get compliance?

But because what – one of the things that we learned is that if all you’re looking for is compliance, you’re not going to get sustainability. The way to get sustainability is engage the people doing the work and get commitment from them to the change and they will make sure it sustains and actually continue improving.

So, how do you help a leader make the shifts in their own thinking and behavior? One of the things that’s difficult for people who are charged with making these transformations is they usually got the spots by being highly effective individual contributors. And people who are good at problem-solving, people who have the answers, people who are good at making things happen, that skillset or that method is not going to work when you’re trying to lead a group of people on a cultural change like this or transformation.

So, how are you able to let go of those things? How do you know what to let go of and what are the things you need to develop in yourself to be successful and make the change?

…and this I think is traditionally what coaching means in the Lean community where you have a coach or a Sensei teaching someone the thinking, the tools, the methods, and then that person being able to transmit that to the people who are actually making the change…

And the way that – this is something that my coaching training really helped me with, it’s kind of the difference between vertical development and horizontal development in a person. And if you think of the vertical development is the transfer of knowledge where you have – and this I think is traditionally what coaching means in the Lean community where you have a coach or a Sensei teaching someone the thinking, the tools, the methods, and then that person being able to transmit that to the people who are actually making the change, the people on the floor so to speak.

So that’s kind of a vertical, in one ear and out the other kind of thing. But the horizontal development I think is in our experience where the Lean transformation, the Lean activities hit a roadblock. It’s like how do you develop the internal capabilities of that leader to take the resources that they already have, the experiences that they already have and apply them to being an effective leader of this change.

So kind of the insight that I got to and that we got to is that these things don’t fail because the methods don’t work. We all know that the methods work, right? PDCA works. If you do it well, you’re going to get the result. It’s people. All these changes are made by people. And effective leaders are good people, developers. So that’s where we focus a lot of our energy.

Tracy O’Rourke: Yeah. I think that’s a very interesting comment because we tell people that do process improvement work, don’t focus on the people, focus on the process. Separate the people from the process and work on the process.

But I think you raised a really important point, Kevin, and that is when it comes to leadership, it is about the person. It is about the people. It is about what the leaders doing or not doing. So I think that is really interesting. And my hope is that anyone listening that is a leader realizes that what they do or choose not to do has a huge impact on the people below them and even next to them.

I just want to ask you one other thing. And of course, you and I had a chance to talk about some of the things that you’re doing, and this is really more around the question of where are you spending your time? Any special project?

So I know that you are on the advisory board for Feeding San Diego, which was formerly Feeding America, and that they have been trying to do Lean as well. And I think it’s great that you’re really spending time helping this organization, this nonprofit, grow and help them apply Lean at the advisory level and beyond.

So can you tell us a little bit about your involvement there and how that happened and what you do for them and anything else you want to share?

Kevin Limbach: I’d be happy to. I’m passionate about this cause so I can talk about it forever if you want me to. So we got involved or I got involved with Feeding San Diego. At the time, they were Feeding America San Diego. And we have an employee-volunteering group here at TaylorMade that I’m part of and we took a group of volunteers down to their distribution center near Mesa on a Saturday morning. And we were helping to sort the food that had been donated by – you have to look at the used by day and sort it into categories so that they could package it up and distribute is to people who needed it.

And of course, we are there with kind of the core Lean team and we’re looking around and we’re saying, “Boy, we could really help them become more efficient in this work.” Because the purpose is so important and impactful, and if they were a little bit better at removing waste from their process and improving the flow, they could feed more hungry people. Wouldn’t that be cool?

So we at the company had been really inspired at one of the LEI summits by a keynote speaker from the Food Bank of New York City who had been helped by the Toyota community outreach people on improving their food kitchens.

So we thought, well, in addition to just having these volunteers go down and devote their muscle for two hours on a Saturday morning, there are other skills that we have at TaylorMade that we could volunteer with. We could do the skills-based volunteering. We can help them be more effective in their mission by applying some of these Lean principles.

So anyway, I got engaged with the leadership there at the time. We started doing some work with them. The folks – a lot of the instructors from San Diego State came in. We did some value stream mapping. Tried to help them reduce their produce waste. They had some metrics and some goals and we were able to apply the Lean principles to that.

So, one of the things that kind of separates Feeding San Diego as an organization is they are very innovative. They have a culture of innovation. So they took to this like ducks to water. And so, I do a little bit of help with them. The Director of Operations there, Alicia Saake, the Chief Operating Officer now, she is really into this and very involved.

TaylorMade donated some time or some money to put some of the Feeding San Diego people through the San Diego State class. And I think actually, you were involved, Tracy, with Mike Osterling and the class this semester with doing the value stream mapping in their facility.

Tracy O’Rourke: Yes. It has been very educational. And doing the tour there and the hosting has been pain-free really. They are so excited and it really just helps with the streamlining of the class. But it really is inspiring the class as well in terms of helping nonprofit. So I’m really hoping that we get more volunteers.

Kevin Limbach: Yeah. Well, one of the – I’ll make a connection back to Lean here. One of the things that Toyota preaches is that you have to start with purpose. And when you think about feeding hungry people, it might not be a refined and more important purpose. And the need is so great. The statistics are mind-boggling. One in eight people in San Diego County are food insecure. There’s a huge percentage of military families that are food insecure.

Forty percent of the food in this country is wasted. So being able to apply some of the thinking to reducing that waste and improving flow really, really means something. You can see that the people who work there are just so passionate and so committed and so creative about fulfilling this mission. It’s just inspiring to be able to be a part of it.

Tracy O’Rourke: Yes. And I brought them up because I know that you’re very passionate about that group and helping that group. And I think you’re a role model for other leaders, Lean leaders, because you’re not afraid to try experiments. You’re not afraid to say, “Hey, this is where we’ve learned and here’s where this was painful but we’re still moving forward.”

You’re not afraid to share your lessons learned. You’re obviously growing yourself. You are listening to your coaching and trying to embrace that. And so, that’s really why I wanted to interview you because I think all of these pieces are really important aspects for a leader to think about especially if they are looking to be a better Lean leader or to your point, just a better leader.

So, I want to thank you for joining me today at the café, Kevin. It was really, really enjoyable talking with you.

Kevin Limbach: Oh, absolutely. My pleasure. I enjoyed doing it.

Tracy O’Rourke: Wonderful.

Getting Started

Sign up for our next webinar, 5 Ways to Engage Yellow Belts and Applying Their Skills After Certification.

Celebrate Wonder Woman Cecilia Martinez, an Assistant Professor at Clarkson University who is a Green Belt, helped improve processes at a local hospital as part of their certification.

And check out the latest success story where Hampton Sublet of UC Davis turned 2,600 wasted hours into value-added work.

And if you have an interest, UCSD’s online Lean Six Sigma Green Belt course is starting on June 25th. You still have time to enroll. Check out our website for more information or go to UC San Diego Extension’s website.

Elisabeth Swan: And you don’t want to miss our next episode where I interview Richard Sheridan, CEO of Menlo Innovations and author of Joy Incorporated. He is a an amazing man who has created a truly inspirational workplace.

And there’s another very groundbreaking hiring practice going on there too.

Tracy O’Rourke: Very interesting. Thanks for hanging with us here at Just-In-Time Café.

Elisabeth Swan: See you in two weeks!

Thanks for Listening!

Listen to more podcasts.

The post Podcast: Just-In-Time Cafe, Episode 33 – Crafting a Lean Culture at TaylorMade Golf, Featuring Kevin Limbach appeared first on GoLeanSixSigma.com.

62 episodes

Crafting a Lean Culture at TaylorMade Golf With Kevin Limbach

Just-In-Time Cafe: Lean Six Sigma, Leadership, Change Management

Archived series ("Inactive feed" status)

When?

This feed was archived on September 13, 2020 23:09 (

Why? Inactive feed status. Our servers were unable to retrieve a valid podcast feed for a sustained period.

What now? You might be able to find a more up-to-date version using the search function. This series will no longer be checked for updates. If you believe this to be in error, please check if the publisher's feed link below is valid and contact support to request the feed be restored or if you have any other concerns about this.

Manage episode 209053560 series 1460675

In this episode, Tracy finds out how Renaissance man Kevin Limbach of TaylorMade Golf helped “infect the organization with great problem solvers.”

For Survey Says, we’ll find out the results of our poll addressing the biggest challenge to completing online training and certification. In the News we’ll tell you all about our tour of Zingerman’s Mail Order business (and their famous cheesecake) and for Q&A, we’ll answer a user’s question about Rapid Improvement or Kaizen Events. Great stuff!

Also Listen On: |

Timeline

- 1:58 Survey Says

- 4:46 In the News

- 10:00 Q&A

- 11:55 Coupon Code

- Special coupon code for all of our awesome listeners: 20% discount on all of our online training!

- 13:07 Today’s Special

- Interview with Kevin Limbach – Vice President, US Operations & Service, TaylorMade Golf Company

- 38:03 This Just In

- Webinar: 5 Ways to Engage Yellow Belts in Applying Their Skills After Certification

- Wonder Women of Quality: Cecilia Martinez

- Success Story: Repurposing 2,600 Hours of Transportation Waste Toward Value-add Work With Hampton Sublett

- GoLeanSixSigma.com Partners With UC San Diego Extension to Offer Green Belt Certification

Podcast Transcript

“One of the things that we learned is that if all you’re looking for is compliance, you’re not going to get sustainability. The way to get sustainability is engage the people doing the work and get commitment from them to the change and they’ll make sure it sustains and actually continue improving.” – Kevin Limbach

Tracy O’Rourke: Hi, everyone. I’m Tracy O’Rourke.

Elisabeth Swan: And I’m Elisabeth Swan.

Tracy O’Rourke: And we are from GoLeanSixSigma.com and you’re listening to the Just-In-Time Café Podcast where we bring you fabulous apps, polls, news, books, and people so you can build your problem-solving muscles.

Elisabeth Swan: Tracy, do you play golf?

Tracy O’Rourke: No. Do you?

Elisabeth Swan: No, and even though this episode has golf in the title, it’s not really about golf, is it?

Tracy O’Rourke: No, it isn’t. But wouldn’t it be cool if you could Six Sigma a golf swing? I’m sure we’d have a lot of people tuning in if we have that answer.

Elisabeth Swan: Let’s discuss it in our private dining room.

What’s on the Menu (Podcast Agenda)

Tracy O’Rourke: There is so much to talk about in this episode, Elisabeth. Tell us what we’re going to be talking about today.

Elisabeth Swan: Of course! This month, we visit the golf course or at least Tracy visits with Kevin Limbach of TaylorMade Golf to find out how they infected the organization with great problem-solvers. Those were his words. I like that.

For Survey Says, we’ll find out the results of our poll question, what is the greatest challenge to completing online training and certification?

In the News, we get to tell everyone about our tour of Zingerman’s Mail Order business and their famous cheesecake.

And for Q & A, we’ll answer a user’s question about what makes a good topic for a kaizen event? I’m still focused on Zingerman’s cheesecake. But we’ll get back to that.

Tracy O’Rourke: And remember to stay tune for this month’s coupon code in order to get a discount on GoLeanSixSigma.com’s online training. Unfortunately, the discount does not apply to Zingerman’s cheesecake.

Elisabeth Swan: Bummer! Let’s get to the poll.

Survey Says

Tracy O’Rourke: I was curious about how they would answer this poll about online learning challenges. It’s not what I expected, Elisabeth.

Elisabeth Swan: You’re right. I thought the biggest challenge would be people having to learn on their own, that sense of loneliness, “I got nobody with me. I’m just me and my computer.” But that was dead last. So I was totally wrong.

So last month, we asked learners, what is your greatest challenge to completing online training and certification? And here’s what we heard:

- Making it a priority was first at 32%.

- Scheduling time on the calendar was second at 23%.

- Guiding through difficult concepts, 20%.

- Staying interested in the material, 14%.

- Working on my own, 11%.

So if you combine making it a priority and scheduling time on the calendar, that’s 55% of the challenge for people. You can see the Pareto chart on our website.

But I recently took an online course and that scheduling was key. So I put on my calendar. It was a daily repeating task. I know at 1 PM every day, I was going to spend an hour completing my course work. So that drumbeat makes a huge difference, at least to me.

So what do you think of these results, Tracy? What’s your advice for your online learners?

Tracy O’Rourke: Well, I agree with you, Elisabeth. I think carving time on your calendar to do the online training is absolutely key and more importantly, committing to it rather than saying, “Oh, I have too much stuff to do. I’m going to de-prioritize it and not do it.”

And so, we’ve been doing a lot of session, group review sessions with some of our clients and unfortunately, they ran into this very thing where they are so busy at work that they actually even have it on their calendar but then they’re not committing to doing the training when it says to do it. And they are filling it with last-minute more important things or urgent things.

So, it could be very difficult to stay committed but you’re not going to finish the training in time if there’s not commitment there.

Elisabeth Swan: Yeah, it would not happen. Take heart. Put things in your calendar and check out our new poll. We just launched it this week where we asked our listeners, who is continuous improvement coach? The options are:

- A. I have an internal coach to meet with regularly.

- B. An external coach meets with me regularly.

- C. I design my own coaching by attending webinars, et cetera.

- D. I have a coach but I never see or meet with them.

- E. I don’t have a coach and I wish I did.

Go ahead and take that poll and we’ll discuss the results next month. I’m Elisabeth Swan and you’re listening to the Just-In-Time Café Podcast. We love your feedback. Please leave a review on iTunes or our website and don’t forget to subscribe!

Tracy O’Rourke: Cool. Up next, it’s In the News.

In the News

Tracy O’Rourke: OK. One of my most favorite things to do with my job is to actually take tours of organizations that are implementing and Lean and Six Sigma. And this was such a revelation, really fun. Where do we start, Elisabeth?

Elisabeth Swan: I don’t even know. Tracy and I as Tracy said, I haven’t done as many as she has but now, I’m hooked. So we took a tour of Zingerman’s Mail Order business in Ann Arbor and my eyes were popping. My ears were popping.

Tracy O’Rourke: Yes. So we have the pleasure as Elisabeth just said of attending this workshop with Jeff Liker and Karyn Ross. And as part of this workshop, we got to tour two organizations, Menlo Innovations which is a software company and Zingerman’s. And both of these organizations are highlighted by the way in their book, The Toyota Way to Service Excellence. So I was really looking forward to visiting both of these organizations because I had already read about them in the book.

And so, I really wanted to see what these organizations were doing. And boy, that was such a great experience. If you were looking for an excellent example of just using takt time, you should go to Zingerman’s. They have that dialed. And it’s crazy how they’ve been able to scale their business to meet customer demand for the holidays because it – what is it? Like it goes tenfold during the holidays or something crazy.

Elisabeth Swan: It gets crazy, yeah. We’ll talk about the other stress that it put on their processes to have – most of their business happen during the holidays. Yeah, they had printer that takt time things well. The printer was printing orders based on takt time. So people would just pull and pick and pack. So those were great.

The other thing that struck me was I love the story that Chief Operating Officer Tom Root told about completely altering their hiring practice.

Tracy O’Rourke: Yeah, that was pretty innovative.

Elisabeth Swan: Yeah. And I think that came out of what you just said. They do most of their business during the holidays. So they have to ramp up their temporary staff by 500 people. It’s crazy. And you and I were there. It’s a warehouse. It’s not a huge warehouse. I’ve seen a lot bigger. But they would have lines out the door and down the street. And this is getting into the holiday season. It’s Michigan. So it’s not nice outside. People were wrapping around the blocks.

And then they had really tired interviewers, people that are talking to thousands of people and getting really tired. So those of you who have ever had the job of interviewing new hires, it’s already a crap-shoot. So the process just ended up being in their case, run by bias.

I think Tom said when they looked at some of those applications, they had 2,000 applications to sift through after this day of interviewing. And most of them, just – the interviewers said, “Nice. Seemed friendly.” So hiring was just based on assumptions. They sat down. They said, “Hey, we’re using this Lean stuff, why don’t we try creating a future state value stream map? Let’s see if we could invent a process that’s better than what we’ve got.”

So, the new process that they designed said they would only take 25 people at a time and they would schedule those 25, each time, for a 30-minute reservation window. So people were not lining up around the block. They knew exactly when they had to be there. They would show up. Name tent was at the desk. They were given a sheet and that was their scorecard.

Then each candidate worked through a series of skills test. They put them right on the job. They tested them by having them do some of the tasks that they’d be doing if they got the job. And if they failed any of the tasks then they’d be taken to a secluded spot and let down carefully and then let out what they called the “No Door.” And he said, “So if they weren’t happy, it’s OK. They’re in a private space.” They can have their emotional moment.

But if they succeed in all the skill tests, then they – everyone claps and cheers and they say, “You’re hired!” since that’s all that mattered. And as long as they can do the work in the 5 remaining then people filled out a job application, which is so it’s after the fact. That’s genius. So there’s no need for those other 1,500 job applications or people they weren’t going to hire. They told them their shift, their first day, and what they’d be doing. End of interview. Hired. Applied. Done.

So they designed that ideal state map and then they built the new process. And it took them a while to perfect it but they fundamentally transformed their hiring process and it’s just really cool.

Tracy O’Rourke: Yeah. I am really impressed with that. That is so cool that they really transformed how they hire people and they applied Lean, which is super cool.

Elisabeth Swan: Yeah. And you can check out a little visual that we took when we were there. You can check out the Lean Six Sigma Everywhere blog for a photo of Zingerman’s Weekender Shadow Boards, one of their most popular gift boxes because it has that cheesecake. But it’s really cool. It’s just a piece of cardboard, right? But they had of course the glossy image of the cheesecake. So yeah, we got hungry.

Tracy O’Rourke: Yup. And if you guys want to send us a gift basket over the holidays, I’d be glad to accept one.

Elisabeth Swan: Happy to accept those. Happy to.

Tracy O’Rourke: I’m Tracy O’Rourke and you’re listening to the Just-In-Time Café Podcast. In a short while, we’ll get to hear my interview with Kevin Limbach, Vice-President of US Operations and Service at TaylorMade Golf.

Next up, it’s a question from our listeners.

Q & A

Elisabeth Swan: So Tracy, you took this question about kaizen events which is the Japanese term for a rapid improvement event, right?

Tracy O’Rourke: Yes. So we had a learner who asked, “What are some good examples of Kaizen events or rapid improvement events?” And really, that’s what a kaizen event is. It’s typically a 2 to 5-day event that a team of people are sequestered to actually get some work done. The specific work is dependent on what the agenda entails.

And the best kinds of kaizen events are the ones that obviously get results. But there are a lot of different kinds of agendas that kaizen events have. You could conduct a process walk and build a value stream map and some people call that a kaizen event or there might be other very specific things like doing 5S or workplace organization or developing visual management.

It’s really important to have it well-laid out with solid goals and objectives and activities that are going to meet those goals, help the team reach those goals.

There have been other events that are even more complicated, developing work sales or poll systems or designing single piece flow for manufacturing floor or plant or product. So, there are lots of things that can happen but I think the big challenge I see is people underestimate the planning of a kaizen event. It’s really important to have it well-laid out with solid goals and objectives and activities that are going to meet those goals, help the team reach those goals.

So if a kaizen event is not successful, here’s the issue. People on your organization are going to be less likely to attend one in the future. So do your due diligence. Don’t waste people’s time. Make sure it’s providing value.

And if you are going to be doing kaizen events regularly, I’d highly recommend buying the book, The Kaizen Event Planner. It’s by our friends, Karen Martin and Mike Osterling. It’s very thorough, very comprehensive, and it will help make your kaizen events successful.

Elisabeth Swan: Great book. I recommend it too. Coming up next, it’s Today’s Special. Tracy, give us a little preview of your interview with Kevin Limbach.

Tracy O’Rourke: Yes. I really had the pleasure of speaking with Kevin Limbach. He is doing so much work at TaylorMade Golf and really making a difference. But he is also donating his time to nonprofits and helping them along the Lean journey as well. So he’ll talk about that as well as some of the trials and tribulations that TaylorMade Golf has encountered on their journey.

So if you want to hear the voice of a leader and how Lean has transformed how they operate, stay tune.

Today’s Special

Tracy O’Rourke: Hi, everyone! Welcome. You’re listening to the Just-In-Time Café. I’m Tracy O’Rourke. And joining me today is Kevin Limbach, Vice-President of US Operations and Service at TaylorMade Golf company. How are you today, Kevin.

Kevin Limbach: Oh, I’m doing great. How are you, Tracy?

Tracy O’Rourke: I’m wonderful. Thanks for coming to the café to share some of your experiences as a leader in process improvement at TaylorMade. So before we get started, let me tell you a little bit about Kevin.

Kevin Limbach’s early career was spent in the printing industry. And since then, he has held various positions in the golf equipment industry over the last 20 years, most recently as VP. He is an active practitioner and proponent of Lean thinking and currently serves on the advisory board of the San Diego State University’s Certification in Lean Enterprise Program.

He is also a graduate of George Mason University and holds professional coaching certifications from the Hudson Institute of Santa Barbara and the International Coach Federation.

He also serves on the advisory board for the Global Supply Chain Management Department at Cal State University San Marcos and on the board of directors at Feeding San Diego.

Welcome, Kevin. You are very active.

Kevin Limbach: Oh yes. Well, I don’t have any trouble staying busy. So thanks for that. That sounded a lot busier than it actually seems.

Tracy O’Rourke: Well, good. So I’m really excited to talk with you. TaylorMade Golf has been on a Lean journey for a while and I’d love to hear a little bit about your experience and a little bit of history of what has been happening at TaylorMade. Would that be OK?

Kevin Limbach: Sure. Absolutely. So, I can give you kind of the rundown of the Lean journey since I came to TaylorMade back in 2006.

Tracy O’Rourke: OK.

Kevin Limbach: So I came with some experience. I had worked at a previous position with some folks who had worked at Toyota. So I learned a little bit about problem-solving and A3 thinking and strategy deployment and problem-solving from them.

And when I came to TaylorMade, there was a pretty active segment of the company involved. They had just done kind of a major transformation from batch processing to cellular flow in the club assembly operation here in Carlsbad. Very well done. Very effective. But that was kind of the extent of it. So not much involvement by the folks in operations at large.

I kind of took some of the experience I had had. Started doing some kaizen events in our warehouse, in our club assembly group and it really got a lot of good response from the folks in the floor, which is what you typically see, right? The people on the floor are dying for this kind of engagement and attention.

And through some of that, some of the report outs that we did, we got the attention of upper management and got the encouragement to go a little bit broader with the efforts.

So the next thing is, we started taking groups of people through the San Diego State Certification and Lean Enterprise Program. We started with about five people and then it was five more people.

So in 2007 and 2008, there were groups going through this, each working on these really effective projects. A lot of them not kind of manufacturing projects. A lot of them were administrative type efforts. And that also got the attention of people here and kind of spurred the effort on.

At any rate, after we had sent about four or five groups through the public program, we decided to bring the training in-house. And I think for two, maybe three years, we were putting 50 people a year through the program here on site. And some of the results of that were very eye-opening for everyone in terms not only the tangible results but the level of engagement and kind of driving the leadership.

We had a kind of a company initiative in time called Distributed Leadership. And this really fit nicely with that. It was a vehicle for that. So at one point, we had gotten so far down the road with this training that we had trained 150 out of the 600 people on campus in this program. And everybody was very enthusiastic about it and the results were great and kind of the environment here at TaylorMade was very competitive. So, these teams were competing with each other and they were kind of over the top in their presentations and it was just – it was really, really fun and impactful at the same time.

And we had a group here that was kind of the gatekeepers or the kind of steering committee I guess you’d say for the Lean involvement at the company. And we got in a room one day and looked around each other and said, “Well, we’ve got 150 people through this program. What kind of support might they need from us to keep taking what they’ve learned and then keep applying it here at the company?”

We decided to get the groups together in small teams, the teams that went through the program together and just ask them. What have you been able to do with what you learned in the training and how come we help you?

And this was another kind of milestone or a Lean journey because when we talked to folks, what we heard was, “Hey, you know what? I was so grateful that I’ve had the opportunity to learn about Lean thinking. I will never look at my job or the world the same way again.” I mean it really teaches you to look at things differently and identify ways, the non-value added processes and really think differently about what we do. But I really haven’t found anything to do with it back on the job.

Tracy O’Rourke: Darn it!

Kevin Limbach: Yeah. Kind of waiting for somebody to give me my next big project. So that was a pretty consistent theme. And so, we got back together and said, “Well, uh-uh. If we were thinking that we were giving people skills and tools to take back to the – where they work and start making improvements, it’s not panning out that way.”

So what we decided to do with that is to focus on PDCA as the tool that we would use to give people – to kind of build on the overview training that they got in the San Diego State Program but to give them some more specific problem-solving capability through doing PDCA, the 8-step problem-solving method, the kind of A3 problem-solving method.

So we were fortunate enough at the time to have hired somebody who had worked at Toyota and really was able to teach us what PDCA really meant and how it really was to be applied. So we developed and we worked with the Lean Enterprise Institute and there’s kind of an offshoot called Honsha that Sammy Obara is affiliated with.

Tracy O’Rourke: Yup. I know Sammy. He lives in Vista. He is a local.

Kevin Limbach: Yeah. Sammy is fantastic. Anyway, so they helped us developed this kind of advanced problem-solving training and we went into it with kind of the philosophy of infecting the company with great problem-solvers. We were going to take people who had shown capability and commitment and kind of the aptitude out of the classes and put them through this advanced training in problem-solving.

So, we started doing that and it really paid off big time for us. Through that, we were able to kind of develop a cadre of about half a dozen people who are skilled in A3 thinking and PDCA problem-solving. And about this time, the company hit a rough patch on the industry took a downturn. We had some profitability issues.

And here, we were as kind of the Lean group, showing up with people who were able and willing to dive into the business problems that we had. And that’s how we focused their efforts and it paid off really big time. It was – we were in exactly the right place with that at exactly the right time as far as the company went.

Tracy O’Rourke: Well, the good news is, it sounds to me like you got a head of the curve. You spent a lot of time training people, getting people excited, having some success with projects, and you didn’t wait until the downturn happened it sounds like. And so when the downturn did happen, you guys were ready really to handle those kinds of bigger issues it sounds like.

Kevin Limbach: Yeah. And that’s a good point. And then let me back up a little bit because there’s a missing piece of the story here that factors into that. Along the time that we had gotten on some tension in the company from kind of the executive team in the company and the CEO of the company, he was very – the CEO at the time was very impressed with the level of engagement and the results he was seeing from the teams that were going through the San Diego State training and said, “Oh, we got to do this for everybody. We got to get the entire company trained on this.”

So we took a run at strategy deployment with the executive team and it was a plane crash. I would have to say.

Tracy O’Rourke: How come?

Kevin Limbach: Trying to take the culture like a sales culture and adapt it to kind of what they viewed as a very process-driven kind of engineering cut and dry strategy deployment process. It just didn’t go. I mean the kind of the organism spit that out.

And so, we had kind of as the group that was leading the Lean effort here, we had to kind of pick ourselves up and dust ourselves off and said, “OK. Look, that didn’t work. So we should just keep doing the right things and keep moving ahead and sooner or later, the business will come back around to us.” And that’s what we did.

So we decided that problem-solving was the right focus. We developed our own kind of limited strategy deployment or Hoshin process to decide where we would focus the problem-solving to get the impact to the higher business goals. And sure enough, the business did come back around and we were in the right place.

There is going to be resistance. There are going to be setbacks. And you just need to keep your eyes on the prize and keep going forward.

So the moral of that story for me is you know what the right things to do are, if you’re a believer, you have to keep believing and you know what the right things to do are and just keep doing the right things and keep moving forward because there are going to be bumps along the way. There is going to be resistance. There are going to be setbacks. And you just need to keep your eyes on the prize and keep going forward.

Tracy O’Rourke: And culturally, you probably learned something because again, these tools work. Lean works. The philosophy works. But it’s really finding what works at TaylorMade or what works at any organization because the deployment of it does look a little different no matter where you go.

Now, you had mentioned earlier that one of the challenges you ran into was that people were sort of waiting around for this, “Where is my next big project?” And so, you incorporated PDCA with the help of Sammy, which I love him too. He is awesome.

So, I wanted to ask you, did that actually help people to constantly apply the process improvement thinking and methodology by implementing some of that? Because you were really – it sounded to me like you really wanted to close that gap of why are people waiting to be told what to work on?

Did the PDCA approach help close the gap so that they were sort of self-starting on their own with process improvement?

Kevin Limbach: Yeah, that’s a great question. And I would say that no, it didn’t for the whole group of people who had gone through it because one of the other things that we learned is as kind of simple as the concepts of PDCA are, it’s very difficult. Very difficult. Much more difficult than you could possibly imagine to train people to really get it. And it’s just so counterintuitive but that’s exactly what we found.

So, the kind of the success rate even with kind of the down selected folks that we put through the advanced training wasn’t one hundred. So it was very difficult.

So not only was it difficult, another thing that we learned is that it requires hands-on, one-on-one coaching to really help people get it and be effective with it. So it’s a pretty big time commitment to evoke the resources to do the training, to carve out the time for people to work on their PDCAs but more importantly, to have someone, a coach, coaching them through this. So think about this as the managing to learn kind of paradigm and have the person working the A3 and then someone coaching them through that.

So what we found is that – our experience was that even with really capable folks, it took a couple of iterations of a coaching through A3s before they were independent. And actually, some people never got there for a variety of reasons. Some of them is kind of mundane as they couldn’t find the time within their jobs to do the work. So …

Tracy O’Rourke: So you’ve been doing this now since 2006 TaylorMade got started and you’ve been there for that. What would you say as a Lean leader, what would you say are some of the key principles that you believe or that you’ve embraced to make this effective in your organization?

Kevin Limbach: Well, I would say the number one thing that I’ve learned is that there’s really no difference between Lean leadership and leadership. So the attributes or the behaviors, the thinking that makes a good leader a good leader and an effective leader are the same things that make a Lean leader a good Lean leader.

And what I mean by that is it’s not as difficult to instill and teach people the technical part of Lean, the concepts, the nuts and bolts, the methods, that kind of stuff. What’s really hard is kind of the adaptive training that you need, the adaptive behaviors.

Now, what are you going to do when you’re responsible for making a transformation in an area and getting people to go along? They’ve been doing things the way they’ve been doing them for years. You don’t have any direct responsibility over them. It’s all through influence. How do you going to deal with the resistance? How are you going to get people to engage in the work and you get commitment instead of just trying to get compliance?

But because what – one of the things that we learned is that if all you’re looking for is compliance, you’re not going to get sustainability. The way to get sustainability is engage the people doing the work and get commitment from them to the change and they will make sure it sustains and actually continue improving.

So, how do you help a leader make the shifts in their own thinking and behavior? One of the things that’s difficult for people who are charged with making these transformations is they usually got the spots by being highly effective individual contributors. And people who are good at problem-solving, people who have the answers, people who are good at making things happen, that skillset or that method is not going to work when you’re trying to lead a group of people on a cultural change like this or transformation.

So, how are you able to let go of those things? How do you know what to let go of and what are the things you need to develop in yourself to be successful and make the change?

…and this I think is traditionally what coaching means in the Lean community where you have a coach or a Sensei teaching someone the thinking, the tools, the methods, and then that person being able to transmit that to the people who are actually making the change…

And the way that – this is something that my coaching training really helped me with, it’s kind of the difference between vertical development and horizontal development in a person. And if you think of the vertical development is the transfer of knowledge where you have – and this I think is traditionally what coaching means in the Lean community where you have a coach or a Sensei teaching someone the thinking, the tools, the methods, and then that person being able to transmit that to the people who are actually making the change, the people on the floor so to speak.

So that’s kind of a vertical, in one ear and out the other kind of thing. But the horizontal development I think is in our experience where the Lean transformation, the Lean activities hit a roadblock. It’s like how do you develop the internal capabilities of that leader to take the resources that they already have, the experiences that they already have and apply them to being an effective leader of this change.

So kind of the insight that I got to and that we got to is that these things don’t fail because the methods don’t work. We all know that the methods work, right? PDCA works. If you do it well, you’re going to get the result. It’s people. All these changes are made by people. And effective leaders are good people, developers. So that’s where we focus a lot of our energy.

Tracy O’Rourke: Yeah. I think that’s a very interesting comment because we tell people that do process improvement work, don’t focus on the people, focus on the process. Separate the people from the process and work on the process.

But I think you raised a really important point, Kevin, and that is when it comes to leadership, it is about the person. It is about the people. It is about what the leaders doing or not doing. So I think that is really interesting. And my hope is that anyone listening that is a leader realizes that what they do or choose not to do has a huge impact on the people below them and even next to them.

I just want to ask you one other thing. And of course, you and I had a chance to talk about some of the things that you’re doing, and this is really more around the question of where are you spending your time? Any special project?

So I know that you are on the advisory board for Feeding San Diego, which was formerly Feeding America, and that they have been trying to do Lean as well. And I think it’s great that you’re really spending time helping this organization, this nonprofit, grow and help them apply Lean at the advisory level and beyond.

So can you tell us a little bit about your involvement there and how that happened and what you do for them and anything else you want to share?

Kevin Limbach: I’d be happy to. I’m passionate about this cause so I can talk about it forever if you want me to. So we got involved or I got involved with Feeding San Diego. At the time, they were Feeding America San Diego. And we have an employee-volunteering group here at TaylorMade that I’m part of and we took a group of volunteers down to their distribution center near Mesa on a Saturday morning. And we were helping to sort the food that had been donated by – you have to look at the used by day and sort it into categories so that they could package it up and distribute is to people who needed it.

And of course, we are there with kind of the core Lean team and we’re looking around and we’re saying, “Boy, we could really help them become more efficient in this work.” Because the purpose is so important and impactful, and if they were a little bit better at removing waste from their process and improving the flow, they could feed more hungry people. Wouldn’t that be cool?

So we at the company had been really inspired at one of the LEI summits by a keynote speaker from the Food Bank of New York City who had been helped by the Toyota community outreach people on improving their food kitchens.

So we thought, well, in addition to just having these volunteers go down and devote their muscle for two hours on a Saturday morning, there are other skills that we have at TaylorMade that we could volunteer with. We could do the skills-based volunteering. We can help them be more effective in their mission by applying some of these Lean principles.

So anyway, I got engaged with the leadership there at the time. We started doing some work with them. The folks – a lot of the instructors from San Diego State came in. We did some value stream mapping. Tried to help them reduce their produce waste. They had some metrics and some goals and we were able to apply the Lean principles to that.

So, one of the things that kind of separates Feeding San Diego as an organization is they are very innovative. They have a culture of innovation. So they took to this like ducks to water. And so, I do a little bit of help with them. The Director of Operations there, Alicia Saake, the Chief Operating Officer now, she is really into this and very involved.

TaylorMade donated some time or some money to put some of the Feeding San Diego people through the San Diego State class. And I think actually, you were involved, Tracy, with Mike Osterling and the class this semester with doing the value stream mapping in their facility.

Tracy O’Rourke: Yes. It has been very educational. And doing the tour there and the hosting has been pain-free really. They are so excited and it really just helps with the streamlining of the class. But it really is inspiring the class as well in terms of helping nonprofit. So I’m really hoping that we get more volunteers.

Kevin Limbach: Yeah. Well, one of the – I’ll make a connection back to Lean here. One of the things that Toyota preaches is that you have to start with purpose. And when you think about feeding hungry people, it might not be a refined and more important purpose. And the need is so great. The statistics are mind-boggling. One in eight people in San Diego County are food insecure. There’s a huge percentage of military families that are food insecure.

Forty percent of the food in this country is wasted. So being able to apply some of the thinking to reducing that waste and improving flow really, really means something. You can see that the people who work there are just so passionate and so committed and so creative about fulfilling this mission. It’s just inspiring to be able to be a part of it.

Tracy O’Rourke: Yes. And I brought them up because I know that you’re very passionate about that group and helping that group. And I think you’re a role model for other leaders, Lean leaders, because you’re not afraid to try experiments. You’re not afraid to say, “Hey, this is where we’ve learned and here’s where this was painful but we’re still moving forward.”

You’re not afraid to share your lessons learned. You’re obviously growing yourself. You are listening to your coaching and trying to embrace that. And so, that’s really why I wanted to interview you because I think all of these pieces are really important aspects for a leader to think about especially if they are looking to be a better Lean leader or to your point, just a better leader.

So, I want to thank you for joining me today at the café, Kevin. It was really, really enjoyable talking with you.

Kevin Limbach: Oh, absolutely. My pleasure. I enjoyed doing it.

Tracy O’Rourke: Wonderful.

Getting Started

Sign up for our next webinar, 5 Ways to Engage Yellow Belts and Applying Their Skills After Certification.

Celebrate Wonder Woman Cecilia Martinez, an Assistant Professor at Clarkson University who is a Green Belt, helped improve processes at a local hospital as part of their certification.

And check out the latest success story where Hampton Sublet of UC Davis turned 2,600 wasted hours into value-added work.

And if you have an interest, UCSD’s online Lean Six Sigma Green Belt course is starting on June 25th. You still have time to enroll. Check out our website for more information or go to UC San Diego Extension’s website.

Elisabeth Swan: And you don’t want to miss our next episode where I interview Richard Sheridan, CEO of Menlo Innovations and author of Joy Incorporated. He is a an amazing man who has created a truly inspirational workplace.

And there’s another very groundbreaking hiring practice going on there too.

Tracy O’Rourke: Very interesting. Thanks for hanging with us here at Just-In-Time Café.

Elisabeth Swan: See you in two weeks!

Thanks for Listening!

Listen to more podcasts.

The post Podcast: Just-In-Time Cafe, Episode 33 – Crafting a Lean Culture at TaylorMade Golf, Featuring Kevin Limbach appeared first on GoLeanSixSigma.com.

62 episodes

All episodes

×Welcome to Player FM!