Go offline with the Player FM app!

How Effective Lean Leaders Model the Way With Danielle Hinz

Archived series ("Inactive feed" status)

When?

This feed was archived on September 13, 2020 23:09 (

Why? Inactive feed status. Our servers were unable to retrieve a valid podcast feed for a sustained period.

What now? You might be able to find a more up-to-date version using the search function. This series will no longer be checked for updates. If you believe this to be in error, please check if the publisher's feed link below is valid and contact support to request the feed be restored or if you have any other concerns about this.

Manage episode 207232624 series 1460675

We have a great line up for this episode of the Just-In-Time Cafe Podcast! For Today’s Special we’ve got Tracy’s interview with Danielle Hinz, the Chief Procurement Officer for King County, Washington.

She’s leaving government for Amazon, but rest assured, she’ll keep using Lean Six Sigma to help government! For “Survey Says” We’ll look at the results of our latest poll to find out the best ways to make time for process improvement, and then we’ll launch our new poll to understand the hurdles involved with completing online training. We’ll cover a school district in Racine, Wisconsin where they use Lean Six Sigma to get better classroom results, and Tracy and Elisabeth just wrote a book! Lots to discuss today!

Also Listen On: |

Timeline

- 2:00 Survey Says

- 5:32 In the News

- 6:42 Book Announcement

- 8:22 Coupon Code

- Special coupon code for all of our awesome listeners: 20% discount on all of our online training!

- 9:44 Today’s Special

- Interview with Danielle Hinz

- 35:07 This Just In

Podcast Transcript

“One thing that I did and think is really important when I came in, I met one-on-one with every employee just to get to know them a little bit and then I did my own process walks with employees, but I could see the way that they were working. And I think that for me, that really opened my eyes about how our folks are working because even though I’ve been in procurement for a long time, everyone’s process is slightly different and to see what that is with my own eyes really helped. And I think it just shows respect for the employees as well and give them the opportunity to show me the work that they do and just seeing how proud they are of how they serve our customers every day.” – Danielle Hinz

Tracy O’Rourke: Hi, everyone. I’m Tracy O’Rourke.

Elisabeth Swan: And I’m Elisabeth Swan.

Tracy O’Rourke: And we are from GoLeanSixSigma.com and you’re listening to the Just-In-Time Café Podcast where we bring you fabulous apps, polls, news, books, and people so you can build your problem-solving muscles.

Elisabeth Swan: I think we should set up a coffee kanban.

Tracy O’Rourke: How would that work?

Elisabeth Swan: So as soon as you finished one cup, we can pull the next one.

Tracy O’Rourke: I do that every day. But I think you’ve reached your whip limit for coffee, Elisabeth.

Elisabeth Swan: And for anybody who has no idea what we’re talking about, we’re sorry. See you in our private dining room.

What’s on the Menu (Podcast Agenda)

Tracy O’Rourke: I know what’s on the menu but why don’t you share it with our listeners, Elisabeth.

Elisabeth Swan: I’m happy to do that. It’s a great lineup. Today’s Special is your interview with Danielle Hinz, the Chief Procurement Officer for King County, Washington. This one is fascinating since she is transitioning from government to Amazon. Stay tune for that one.

We’re going to look at the results of our latest poll. Listeners told us how they make time for process improvement.

We’ll cover some great work going on at the Racine Unified School District. Great to hear when education gets a boost from Lean Six Sigma.

And Tracy and I just wrote a book, lots to discuss today.

Tracy O’Rourke: Woohoo! Remember to stay tune for this month’s coupon code in order to get a discount on GoLeanSixSigma.com’s online training.

Elisabeth Swan: Let’s get to the poll.

Survey Says

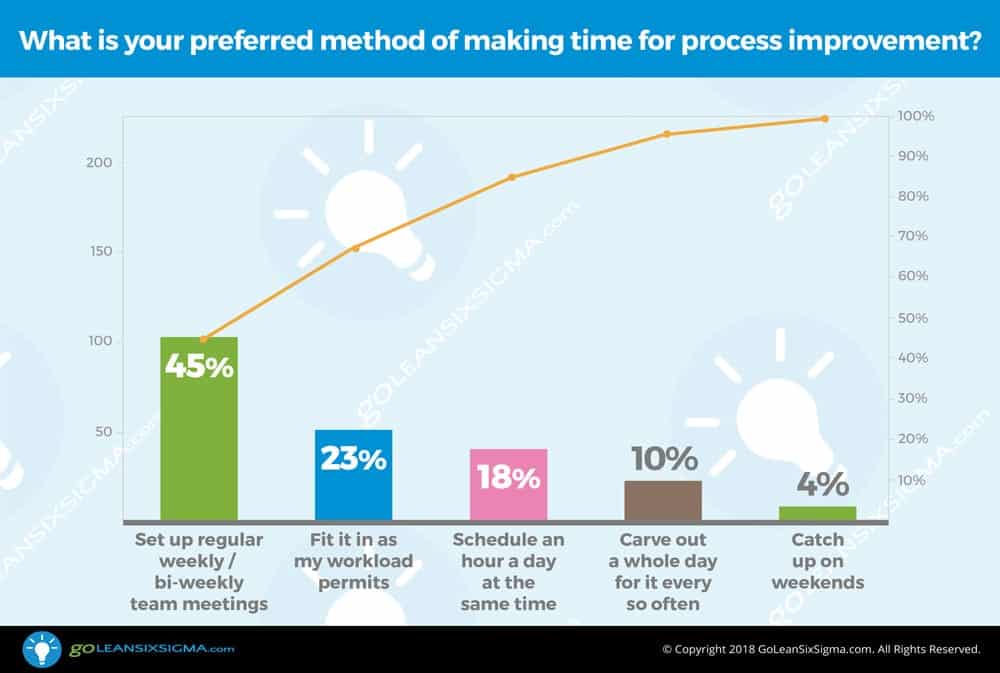

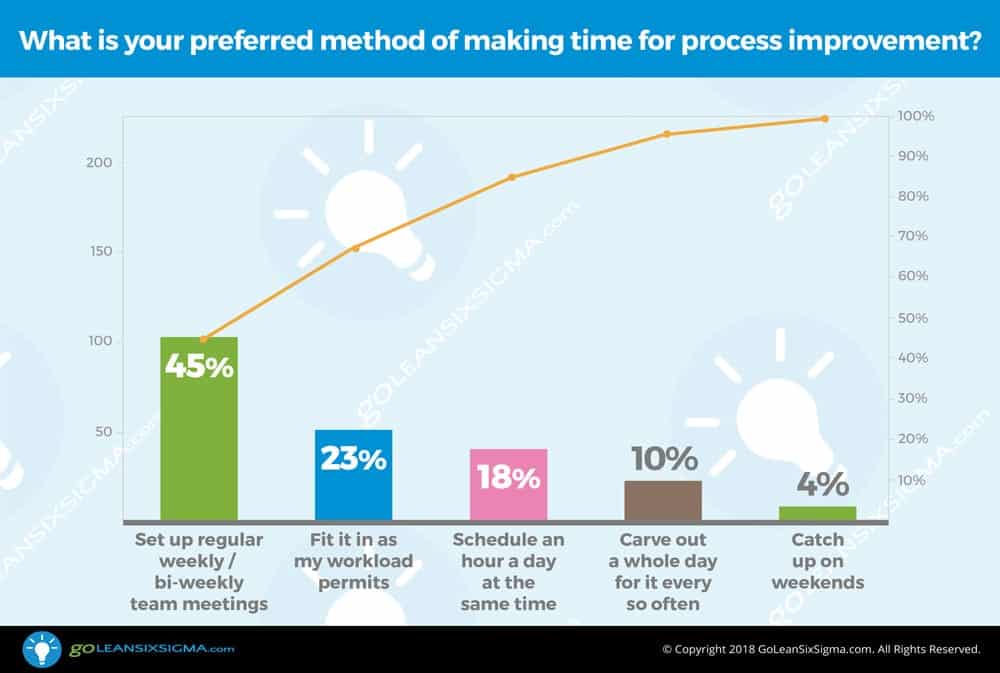

Tracy O’Rourke: This poll addressed the not enough time to get stuff done problem.

Elisabeth Swan: Right. This month we asked listeners how they like to schedule improvement work. Our survey question was, what is your preferred method of making time for process improvement?

And the options we gave people were:

- A. Schedule an hour a day at the same time.

- B. Set up regular weekly by weekly team meetings.

- C. Carve out a whole day for it every so often.

- D. Catch up on weekends. (I hope this doesn’t win.)

- E. Fit in as my workload permits. (Also a bad one I think.)

So the big winner at 45% was set up regular weekly by weekly team meetings, which is great to hear. What we’ve seen work best is some kind of a drumbeat even if it’s for yourself or if it’s for your team. And obviously, when you schedule time with other people, it puts a little more onus on you to make the meeting, to make time to put in your schedule.

If it’s just you, sometimes you blow it up going, “Just made a meeting with myself so who cares?”

So if you make it with other people then it becomes not just a meeting but a work meeting. Sometimes people change the name of those meetings to call it project workshop from 10 to 1 or whatever.

So, it’s a great way to set aside that time. Make sure that things happen. So that’s a great technique. And I’m happy to see the poll results reflect that.

Tracy, do you want to go over the rest of the poll results?

Tracy O’Rourke: The runner-up was fit in as my workload permits at 25% and almost the same percentage, 18, schedule an hour a day, 10% carve out a whole day every so often, and then there’s 4% that catch up on weekends.

So it’s a little concerning that people say, “Well, when my time permits. When my schedule permits, I’ll fit it in.” Because often, that means it’s not a high priority and that’s why sometimes projects take so long because we’re not actually making it a priority and fitting it in.

Elisabeth Swan: No.

Tracy O’Rourke: I really like it actually when you have these meetings that it’s not one way dialogue too. That it’s working meetings. You’re actually getting some work done as opposed to just having people give you updates. So those are a lot more fun too. It’s a great way to engage people. So hopefully when you’re having these meetings, you’re actually getting work done in the meetings not just checking on people.

Elisabeth Swan: Yeah. And as you just used the word, upping engagement, that’s always what you’re looking for with these projects. So you get a lot going on with just that one activity. So great results. Thanks everybody for chiming in on that poll.

Another issue we are aware of is that not everybody completes online training. It’s a great option but sometimes things get in the way. So we want to launch a poll to understand what are the challenges to completing online training and getting certification?

So here’s the next month’s poll:

What is your greatest challenge to completing online training and certification?

- A. Scheduling time on the calendar.

- B. Making it a priority.

- C. Staying interested in the material.

- D. Working on my own.

- E. Getting through difficult concepts.

So pick the greatest challenge for you and the poll is up now. So go ahead right on our website and enter your selection to the poll and we’ll report on it next month.

Tracy O’Rourke: Cool. I’m Tracy O’Rourke and you’re listening to the Just-In-Time Café Podcast. We’d love your feedback so please leave us a review on iTunes or on our website and don’t forget to subscribe.

Up next, it’s In the News.

In the News

Tracy O’Rourke: So Elisabeth, what’s going on in the Racine Unified School District?

Elisabeth Swan: This next news item comes to us from the Journal Times in Wisconsin and it’s written by Caitlin Sievers.

Kamaljit Jackson is Senior Accountability and Efficiency Officer at Racine Unified School District. And she has worked to ensure the whole school board went through White Belt Training, which is pretty big. And she just wanted to get the basic principles of Lean Six Sigma. And she is working to get improvement ideas from staff in all departments. She is asking teachers, janitors, secretaries, central staff members. She is doing a ton of outreach and making sure there’s a very high level of involvement.

The district already has used this practice to review their enrollment process and to develop changes in the middle school. So they’re already putting it into play. They are also using data from various student assessments to ensure classroom strategies are also effective. So they’re going right to a classroom level, which is great.

I just love hearing that process improvement is being applied to the educational system. We love to hear more from Kamaljit Jackson. Sounds like she is a mover and a shaker. We’ll have to reach out to her.

Tracy O’Rourke: Yes, bravo! Thank you for trying to make our educational systems better. I appreciate it being a mom.

Book Announcement

Elisabeth Swan: I’m Elisabeth Swan and you’re listening to the Just-In-Time Café Podcast. In a short while, we will get to Tracy’s interview with Danielle Hinz of King County, Washington. But first, we need to tell you about our new book!

Tracy O’Rourke: Yeah, we wrote a book!

Elisabeth Swan: We did! We’ve never done it before. And it took a while.

Tracy O’Rourke: It is a tool book. But it’s like no other tool book you’ve ever seen, not that we’re biased.

Elisabeth Swan: We got a lot of requests from people who use our online training as well as our listeners.

Tracy O’Rourke: And people just want a simple guidebook with a few basic tools, some instructions, some examples, and how about not boring. Super fun.

Elisabeth Swan: So, we created The Problem-Solver’s Toolkit: A Surprisingly Simple Guide to Your Lean Six Sigma Journey. We wrote it in a style of a road trip so there’s travel kits, instructions on how to avoid potholes as well as some sightseeing when you want to know more about a topic.

Tracy O’Rourke: And it includes some stuff at the Bahama Bistro just like the training. And they provide examples along the way. It’s full of infographics and lots of great visuals. And again, we built it to make it easy for everyone anywhere to build their solving-problem muscle and it’s fun. It’s like going out on a road trip but for your Lean Six Sigma journey. And I love road trips. How about you, Elisabeth?

Elisabeth Swan: I’m totally into road trips. We cover 35 basic tools and concepts to get you on your way. It’s an eBook. It’s free with Green or Black Belt Training.

Tracy O’Rourke: And you can also buy it for 29 bucks on our site and it’s available on Amazon too.

Elisabeth Swan: Did we mention we are really proud of it?

Tracy O’Rourke: We could always mention it again. And a big shout-out to Julius Pecson who partnered with us on the graphics and to Sion Lee who created the Bahama Bistro and all its inhabitants in the first place.

Elisabeth Swan: Tracy, we wrote a book! Coming up next, it’s Today’s Special. Tracy, give us a little preview of your interview with Danielle Hinz.

Tracy O’Rourke: So I’ve had the pleasure of working with Danielle Hinz and seeing her positive leadership impact and influence on her team. She is an exceptional leader and she has been trailblazer with combining leader standard work concepts and straight up leadership development for teams. That includes things like huddles, visual boards, A3 coaching, and she has been working Integris to spearhead leadership development and building cohesive teams.

And although she is leaving government and I know that they are sad to see her leave, her new role at Amazon will still be involving and making government better. I’m really excited to talk with her.

Today’s Special

Tracy O’Rourke: You’re listening to the Just-In-Time Café. I am Tracy O’Rourke. And joining me today is Danielle Hinz. Danielle’s role currently is the Chief Procurement Officer at King County. She is the Value Stream Manager for the $2 billion Procure to Pay Value Stream. And she has a staff of over 60 and they are serving the 13th largest county in the United States. Welcome, Danielle. How are you?

Danielle Hinz: I am wonderful. Thank you for having me.

Tracy O’Rourke: Well, let me tell you a little bit about Danielle. She has a master’s degree in Public Administration. She has been doing this work for 20 years plus in public procurement. And I have had the pleasure of working alongside of Danielle and I have observed that she is an excellent leader. People love her. She has a very forward-looking vision. She inspires others to act. She does not micromanage. And she also streamlines policies, implements better procedures, and overall reduces lead time in the Procure to Pay Value Stream for her customers.

Sadly though for King County and her staff, Danielle’s last day as Chief Procurement Officer is today. She is moving into a new role with Amazon because they are also in Seattle or Washington I should say.

So, what are you going to be doing there, Danielle?

Danielle Hinz: So, I will be going to Amazon Business as part of their government team and I will be working in their local government area. So it’s sort of a new role for them and for me. So I am excited to get started in that opportunity and see what that makes available to me but very sad to be leaving King County. It’s a wonderful organization and I think we’ve been doing a lot of great work here.

So I’ll definitely be keeping in touch to make sure that they continue on this direction forward and upward that they’ve been on here for several years.

Tracy O’Rourke: Yes. You are going to be very much missed I’m sure. And it’s nice that we see – I mean you are moving to a private sector but you’re still helping government. So in that way, that’s wonderful.

Danielle Hinz: Yeah. And I’ve committed my career to government procurement and feel very strongly about public service. And so, it was important to me that even in the new role, I will still be helping out with that same mission.

Tracy O’Rourke: Yes. Good. Very exciting. So people still – you’ll still be on the pulse of things and people could still reach out to you if they miss you and tell you how much they miss for at least two years.

Danielle Hinz: Absolutely yes.

Tracy O’Rourke: And I’m sure it will happen. OK. So what I’d love to talk with you about today is some of the significant impacts I’ve seen in working with you at Financial Business Operations Division in King County and sort of just your Lean journey and a little bit more about what your role in that journey has been as a leader.

So you came to FBOD from Colorado and started working there. And I would love to hear you talk a little bit about coming into this organization and they were just getting started with building their problem-solving culture. How did you feel about coming in with a program when you got started with FBOD?

Danielle Hinz: So coming in, I had a very small experience with Lean I would say. The organization where I come from in Colorado was trying to use those principles but not anywhere near to the extent that they were here in Finance and Business Operations.

So what I appreciated, there was a framework that was being provided for how we do process improvement and how we build employee engagement in our culture so that folks can really be inspired to focus on serving the customer in better ways and finding efficiencies in their process.

So what I appreciated, there was a framework that was being provided for how we do process improvement and how we build employee engagement in our culture so that folks can really be inspired to focus on serving the customer in better ways and finding efficiencies in their process. That sort of outcome has always been important to me and in procurement, that’s what we always get charged with from our customers is be faster in what you do and provide it to us for cheaper.

So we’re always trying to improve processes but what I appreciated about here like I say is that there was that framework of Lean to do that within. And that’s always great to have those tools and vernacular that folks can know what you’re talking about so that as they do improve their processes, they have some tools to do that.

Tracy O’Rourke: So you’re fairly new to some of this process improvement stuff is what you were saying.

Danielle Hinz: Yeah, certainly within the context of Lean. Yes.

Tracy O’Rourke: So what was it like coming in with this sort of mandate? Mandate I say because there’s always the hope that people are going to want to do it. What did you think? Were you’ve kind of taken aback? Were you excited? What was your feeling behind kind of getting started with something like that?

Danielle Hinz: For me, I was excited because like I say, I think having the structure in place to do process improvement and show successes in that area and be able to identify other room – other areas where there’s room for improvement is really good. And I’ve always appreciated being able to make stuff visible and the use of visual management, visual controls here in FBOD was already in place and lots of whiteboards on the wall and whatnot.

So the opportunity to be able to use that tool to figure out what’s going on and how we can make things better I think was very exciting to see that that stuff was already in existence and folks already sort of knew the philosophy was around it I guess even if they weren’t using it on a regular basis.

Tracy O’Rourke: So there were some tools and approaches that you’ve mentioned. Visual boards and problem boards and huddles and leader standard work, all of these things were things that FBOD implemented to start to build problem-solving muscles and develop a Lean culture. What did you think about those tools and those applications? Did you feel like some of them were more successful than others or did you have one that feel like worked really well?

Danielle Hinz: So I think they all have their place I guess is what I would say. And I think the challenge especially when I was newer to the organization was figuring out where the right place was to insert the different tools. When I came, folks have been trained on A3s and there was a lot of focus on determining what the problem statement was and getting that right and then looking into root causes and doing some analysis of the data and then socializing that with others who are involved in the process.

So folks are really trained on the A3 but kind of its use was sporadic I would say. And then we definitely had visual boards up. I think that they weren’t being used as a management tool to the extent that certainly they are today or that they were intended to be used. And I think – so we’ve really tried to figure out where is the place for those in process improvement.

And truly, I think that you throw a bunch of tools at people and they get a little overwhelmed with it. So kind of breaking it apart and saying, “OK, we’re going to focus on filling out a good A3 right now and then we’re going to go to the tier board and figure out how do we want to display the information and how do we want to then huddle around that information and on what frequency and kind of just coming up with a cadence of those things has been useful. And just starting at the beginning and working through it in terms of finding the problem.

I think problem boards for us were really useful because it gave people a place to post the problems that they saw in the work so that even if they couldn’t do anything at that time with that problem, at least it was somewhere in work that was getting to them.

I think problem boards for us were really useful because it gave people a place to post the problems that they saw in the work so that even if they couldn’t do anything at that time with that problem, at least it was somewhere in work that was getting to them. They could post that problem somewhere that was visible and they didn’t feel like it would get lost. So that helps kind of get the problem and then having folks being able to figure out how to write a good problem statement, who to involve in the socialization of a problem and determining what the root causes were. It’s very important.

And then I think being able to create some way of showing that on our tier boards and like I say, coming up with sort of a cadence of how frequently are we going to look at this information and then what are we going to do about it when we do look at it and have some conversations about it.

So I think all of these tools are useful but I think that you have to decide where to start and just start with a few tools and then build as you go because I think the other tools become more important as you move through the process.

Tracy O’Rourke: Yes. So of the five sections at FBOD, you guys were really the first group to decide that you’re going to have an established daily huddle in front of your board. So, how has that improved your team in general? So have you noticed how that has helped?

Danielle Hinz: Yes. We’ve been doing – our leadership team has been doing daily huddles now for probably close to a year. And I was really inspired to do this in going to a Lean tour Nordstrom’s. They have some of their teams that were doing daily huddles in front of a visual board. And I came back and wanted to try it because some of the problems they were using their board to solve were problems that I felt we had as well.

So primarily, it was that we and the leadership team rely on each other for a lot of different things including information that go back and forth between teams. And there were some gaps there in terms of folks getting information in a timely manner.

Folks also wanted to know what was going on in other areas especially as it may impact their own team and what was going on at any given day. So we started huddling like I say about a year ago. We designed a tier board that we huddle in front of every day that collects some of this information and tracks it. I think we’re on about version 5 on that board now, maybe even 6.

So it has definitely been evolving to meet the needs but it has really helped the information flow. Folks know who is waiting on them for what information and when it’s due by. We check it on that every day. So if there are questions about what the expectation is or when it’s needed or if there are hiccups and being able to pull something together. We’re able to address that on a daily basis instead of waiting until it’s due and then going, “Oh crap! I couldn’t get it because I didn’t understand what you were looking for or something like that.”

And people really quite honestly hate having their name on the board. Somebody is waiting on me. So people hate having their name on the board. And so, folks are getting stuff done ahead of deadlines and whatnot just so they can get their name off the board.

So yeah, it has been super effective and it also quite honestly, we do it first in the morning. So 8:00 o’clock every day we huddle and it’s a really good way just to start the day, get a temperature of where everybody is at, if there is something going on that somebody needs to address. We are able to do that first thing in the morning. So it has been really good for the whole team.

Tracy O’Rourke: So one thing I think leaders do struggle with, it’s something you mentioned that you have done successfully. You said you’re on version 6 or 5, one of the two.

Danielle Hinz: Yeah.

Tracy O’Rourke: And sometimes people just say, “We tried it. It didn’t work.” And they don’t do – my sense is that they’re not necessarily gathering feedback from the people that use the board. So tell us a little bit about how you were able to allow that to happen and promote that?

Danielle Hinz: Yeah. So when I came back from Nordstrom’s and threw the idea out, I sort of mocked something up on a tier board and said, “There are the problems that I’ve seen that I’m trying to address. Let’s get some feedback.”

And fortunately, I think we have a pretty high-performing team already so getting feedback is not usually a problem. So I mocked something up. We huddled at it one day. We talked about how we wanted to see and I sketched it out and we just started huddling there.

And quite honestly, after about a couple of weeks of doing that, it was obvious that we needed to already make some changes. So we made the changes. We raised what we had and put up something new. And now, we’ve done that a few more times.

And so, it is never that it didn’t work at the time that we started. It’s that our conversations evolved and we get a little bit better at one thing. And so maybe we don’t need to track that as much and so we realized we need to start tracking something different or in a different way. And so, we iterate the board so that we start capturing those things that are now important to us.

But yeah, our team, they don’t hesitate to give feedback. But I always allow the opportunity to folks feel like they’re more comfortable putting that on a sticky note and flapping it up there. And a little bit safer environment than let’s talk about how we want to change it. Not everyone is able to participate fully in a way like that. So always leaving room for put your stickies up on the board if you feel like there’s something up here you want to change or you want to talk about. So we do that too.

Tracy O’Rourke: That’s wonderful. So I always say that that’s sort of making a forum for extroverts to talk because the extroverts will tell you what they think. And I know who the extroverts are in your team. And then for the introverts who don’t really want to partake in that kind of engagement as much, they can put Post-Its. So it’s wonderful that you were able to channel that. So that I’m sure they appreciate.

So, I want to talk a little bit about some of the things that I know FBOD was doing that is sort of I guess it wouldn’t be the most common route for establishing a Lean culture, they spent a lot of time training and integrating what I would call soft skills and/or leadership training. Things like the 5 behaviors of a cohesive team, the leadership challenge. Both of those with Integris is I think the organization that was helping you with that.

And then also crucial conversations. So how do you feel about those pieces that were implemented to help build leadership and the problem-solving culture?

Danielle Hinz: So I think they’re absolutely critical to the success that we’ve had. And actually when I came in, sort of acknowledged that we had some more room to improve in terms of the culture that we had. And so, the leaders had gone through leadership challenge which I think brings again some shared vernacular and really helped to then kind of re-center yourself as a supervisor because when you’re in a management position but in a Lean culture, it’s really about coaching employees and enabling them to solve the problems that they find in their work. Whereas the typical role of a manager might be to just solve the problems that employees bring to us, and that’s what they expect and that’s what we think we’re expected to do.

And so, I think the leadership challenge was really critical in terms of shifting the thinking of our leaders about how we interact with our employees and kind of resetting the expectation almost of what our role is as it relates to problems that exist in our business processes.

So I think being able to have shared vernacular around we need to enable others to act, we need to be challenging the process because we’re modeling the way for our employees and we need to inspire that shared vision around where are we headed and why are we doing this anyway. And then of course just recognizing that in terms of encouraging the heart, the employees are people too and we need to make sure that we are paying attention to their personal needs as well. So I think it’s just – it’s critical to reset the expectation of what leader’s role is in a Lean environment.

And then in terms of the 5 behaviors of a cohesive team and crucial conversations, I just think it’s really important for – I’ve always been a fan of team building and I think there are different models out there. But I think these models have been really effective for our teams just to understand how it is that you can get to a really high-performing team in terms of having mutual respect, that conflict is good. You can have healthy conflicts.

And then giving folks the toolset of crucial conversations about how do you actually have healthy conflicts so that both parties walk away feeling like that was a productive experience rather than somebody going like, “Whew! I got that off my chest.” And the person is feeling a little beaten down in the process.

I think teaching folks how to do that was really important for us. And I think just for teams to understand that it’s those things that make us have really great results at the end has just been really useful. And our leadership team actually did our 2-year check-in on 5 behaviors of a cohesive team and we’re continuing to see improvement in how folks interact with each other.

And let’s face it. You’re going to have hiccups and conflicts in understanding what the role of that is and how we deliver results to our employees and our customers I think is really important to keep us focused on how important it is to engage productively in conflict and hash those things out with each other as they arrive.

Tracy O’Rourke: So they have the tools so when they do have conflict and I know that sometimes yeah, just like you said, sometimes managers shy away from conflict because they don’t necessarily know how to handle it or what to do. And having that productive conflict and challenging the process, those pieces I think – how do we make that better and how do we actually mind for that are very positive things that I think people avoid.

Danielle Hinz: Yeah. And I think just actually talking about how you’re supposed to be having conflict because I think sometimes we’re sort of trained to be nice. And so, people then think that if you are having conflict to someone that must mean you’re not doing what you’re supposed to be doing. But in actuality, talking about how there’s healthy conflict and that’s what we need to be having in order to make sure we’re really looking at an issue from all sides and taking into account everyone’s perspective to come up with the best result, I just think that’s really important to set that expectation.

Tracy O’Rourke: So your – I mean your group in particular, really embraced it and I want to believe it’s because you are a really good leader. You really embrace these tools. And ultimately, I think what’s interesting is your employee engagement scores have increased over the last couple of years too. So you guys doing employee engagement score and I also noticed that there was an – that was also increasing. Can you tell us a little bit about that?

Danielle Hinz: Yeah. So starting about three years ago, the county started doing annual employee engagement scores. And you are exactly right, over the 3-year course of those for Procurement and Payables, we have increased each year and we have continued to be on kind of a high end of the county quite honestly. We have a higher score than most other folks in the county and so does FBOD.

And so, I really do think it’s pointing at the Lean culture and the things that that needs to have in order to be successful, which is engaged employees, employees who feel like they can make a difference, and then having them actually make a difference.

So I think where we’ve seen success is by really encouraging employees to participate in process improvements that positively impact their work and then for them to see the results of that which if their own process is better, that’s awesome. But if their customer’s process is better, that’s even awesomer. And that’s what we’re really doing is we’re making our customer’s experience with our processes better and that is because our employees are embracing process improvement through Lean and figuring out ways to improve the customer’s experience.

And so, when they see that happening, I think they feel better about the work that they’re doing and feel supported by their leadership team and it just makes a much better overall environment for them to come to work in every day.

Tracy O’Rourke: Yes. So really, it’s a tremendous success story. So I’m really glad you are taking that time to speak with me and share your experiences with our audience because you have measurable success in terms of what you’re doing with Lean, how that is affecting your teams, the productivity, your employee engagement.

And those are very hard things to measure and the kind of improvements you’ve seen over the last three years are pretty significant. I can’t argue with that.

What advice do you have for leaders about being a better Lean leader?

Danielle Hinz: So I think just patience quite honestly and consistency and that you have to model the way. I think we have to take baby steps like I was saying earlier. I think start with a couple of the tools and get really good at those and then start figuring out how to make other tools work for you as the culture matures I guess in terms of how it’s using Lean. And you can introduce some other tools and folks can see the benefit of those.

And I think just being consistent in terms of the expectations for doing this work are not going to go away. What I heard when I came about three and a half years ago as a lot of folks saying, “We’re just going to wait it out. This is kind of the latest thing and this is going to go away eventually also so we don’t really have to embrace it.”

And I think just being consistent that no, this is really the way that you are expected to do this work now and giving them the room to do that, the folks who are saying they didn’t have the time to work on their process, so we gave them the ability to book time on their calendar to work on their processes instead of in their processes.

And so I think just sort of reiterating in every way that you can that this is important work and it’s here to stay is really important for employees to hear and to understand.

…supervisors taking on problems themselves and solving those problems, having conflict with others, healthy conflicts with others and it’s coming out with a good result at the end, and just supporting employees, all those things are critical to the success of a Lean culture.

And I think as leaders, we have to model the way. So I think the leadership team having tier bards that we interact with on a regular basis on supervisors taking on problems themselves and solving those problems, having conflict with others, healthy conflicts with others and it’s coming out with a good result at the end, and just supporting employees, all those things are critical to the success of a Lean culture.

And I think one thing that I did and I think is really important, when I came in, I met one-on-one with every employee just to get to know them a little bit and then I did my own process walks with employees so that I could see the way that they were working. And I think that for me, that really opened my eyes about how our folks are working because even though I’ve been in procurement for a long time, everyone’s process is slightly different.

And so seeing what that is with my own eyes really helped. And I think it just shows respect for the employees as well and give them the opportunity to show me the work that they do and just seeing how proud they are of how they serve our customers every day I think is – they want their management to understand that. And I think giving them the opportunity to do that has been very critical.

Tracy O’Rourke: Well, I think every leader should follow that advice if they don’t already. So that was wonderful. So setting expectations, modeling the way, showing respect for people, those are three really good insights.

And I really appreciate you coming to talk with us on the café today. Is there anything else you want to share with our audience?

This is how employees get inspired to come to work every day and show up with their best foot forward.

Danielle Hinz: No, I don’t think so except just I would just put in another plug. This is really important work. This is how employees get inspired to come to work every day and show up with their best foot forward. And so, it is really important. It just takes a while. You have to have patience because the culture especially in larger organizations just takes longer to shift.

But at the end of the day, employees really appreciate having a culture where they know their work is valued and that they are respected and that’s how they do their best every day. And when the time comes for them to leave the organization for whatever reason, they have really good things to say about having worked at the county. And I think that’s important too.

Tracy O’Rourke: So, you can find, if you want to ask Danielle more questions or pick her brain a little bit more because she is definitely a model leader, a great mentor for any female out there or male…

Danielle Hinz: Oh, thanks.

Tracy O’Rourke: …you can find her on LinkedIn, Danielle Hinz, that’s H-I-N-Z, Danielle with two L’s, right?

Danielle Hinz: Yup, yup.

Tracy O’Rourke: And we’ll look for you in Amazon as well. So thanks for coming to the café, Danielle.

Danielle Hinz: Yeah. Thanks for having me. It was fun.

Tracy O’Rourke: It was.

This Just In

Check out the latest success story webinar, Lesley Guertin of Cape Cod Child Care reduced classroom incidents by 50%. Another great example of using process improvement in education. And sign up for our next webinar: How Yellow Belts can Apply What They Learned in the Real World.

Elisabeth Swan: And join us for our next podcast episode where Tracy interviews the Vice-President of US Operations and Service at Taylormade Golf company, Kevin Limbach.

Tracy O’Rourke: Thanks for spending time with us at the Just-In-Time Cafe.

Elisabeth Swan: We’ll be back in two weeks!

Thanks for Listening!

Listen to more podcasts.

The post Podcast: Just-In-Time Cafe, Episode 32 – How Effective Lean Leaders Model the Way With Danielle Hinz appeared first on GoLeanSixSigma.com.

62 episodes

How Effective Lean Leaders Model the Way With Danielle Hinz

Just-In-Time Cafe: Lean Six Sigma, Leadership, Change Management

Archived series ("Inactive feed" status)

When?

This feed was archived on September 13, 2020 23:09 (

Why? Inactive feed status. Our servers were unable to retrieve a valid podcast feed for a sustained period.

What now? You might be able to find a more up-to-date version using the search function. This series will no longer be checked for updates. If you believe this to be in error, please check if the publisher's feed link below is valid and contact support to request the feed be restored or if you have any other concerns about this.

Manage episode 207232624 series 1460675

We have a great line up for this episode of the Just-In-Time Cafe Podcast! For Today’s Special we’ve got Tracy’s interview with Danielle Hinz, the Chief Procurement Officer for King County, Washington.

She’s leaving government for Amazon, but rest assured, she’ll keep using Lean Six Sigma to help government! For “Survey Says” We’ll look at the results of our latest poll to find out the best ways to make time for process improvement, and then we’ll launch our new poll to understand the hurdles involved with completing online training. We’ll cover a school district in Racine, Wisconsin where they use Lean Six Sigma to get better classroom results, and Tracy and Elisabeth just wrote a book! Lots to discuss today!

Also Listen On: |

Timeline

- 2:00 Survey Says

- 5:32 In the News

- 6:42 Book Announcement

- 8:22 Coupon Code

- Special coupon code for all of our awesome listeners: 20% discount on all of our online training!

- 9:44 Today’s Special

- Interview with Danielle Hinz

- 35:07 This Just In

Podcast Transcript

“One thing that I did and think is really important when I came in, I met one-on-one with every employee just to get to know them a little bit and then I did my own process walks with employees, but I could see the way that they were working. And I think that for me, that really opened my eyes about how our folks are working because even though I’ve been in procurement for a long time, everyone’s process is slightly different and to see what that is with my own eyes really helped. And I think it just shows respect for the employees as well and give them the opportunity to show me the work that they do and just seeing how proud they are of how they serve our customers every day.” – Danielle Hinz

Tracy O’Rourke: Hi, everyone. I’m Tracy O’Rourke.

Elisabeth Swan: And I’m Elisabeth Swan.

Tracy O’Rourke: And we are from GoLeanSixSigma.com and you’re listening to the Just-In-Time Café Podcast where we bring you fabulous apps, polls, news, books, and people so you can build your problem-solving muscles.

Elisabeth Swan: I think we should set up a coffee kanban.

Tracy O’Rourke: How would that work?

Elisabeth Swan: So as soon as you finished one cup, we can pull the next one.

Tracy O’Rourke: I do that every day. But I think you’ve reached your whip limit for coffee, Elisabeth.

Elisabeth Swan: And for anybody who has no idea what we’re talking about, we’re sorry. See you in our private dining room.

What’s on the Menu (Podcast Agenda)

Tracy O’Rourke: I know what’s on the menu but why don’t you share it with our listeners, Elisabeth.

Elisabeth Swan: I’m happy to do that. It’s a great lineup. Today’s Special is your interview with Danielle Hinz, the Chief Procurement Officer for King County, Washington. This one is fascinating since she is transitioning from government to Amazon. Stay tune for that one.

We’re going to look at the results of our latest poll. Listeners told us how they make time for process improvement.

We’ll cover some great work going on at the Racine Unified School District. Great to hear when education gets a boost from Lean Six Sigma.

And Tracy and I just wrote a book, lots to discuss today.

Tracy O’Rourke: Woohoo! Remember to stay tune for this month’s coupon code in order to get a discount on GoLeanSixSigma.com’s online training.

Elisabeth Swan: Let’s get to the poll.

Survey Says

Tracy O’Rourke: This poll addressed the not enough time to get stuff done problem.

Elisabeth Swan: Right. This month we asked listeners how they like to schedule improvement work. Our survey question was, what is your preferred method of making time for process improvement?

And the options we gave people were:

- A. Schedule an hour a day at the same time.

- B. Set up regular weekly by weekly team meetings.

- C. Carve out a whole day for it every so often.

- D. Catch up on weekends. (I hope this doesn’t win.)

- E. Fit in as my workload permits. (Also a bad one I think.)

So the big winner at 45% was set up regular weekly by weekly team meetings, which is great to hear. What we’ve seen work best is some kind of a drumbeat even if it’s for yourself or if it’s for your team. And obviously, when you schedule time with other people, it puts a little more onus on you to make the meeting, to make time to put in your schedule.

If it’s just you, sometimes you blow it up going, “Just made a meeting with myself so who cares?”

So if you make it with other people then it becomes not just a meeting but a work meeting. Sometimes people change the name of those meetings to call it project workshop from 10 to 1 or whatever.

So, it’s a great way to set aside that time. Make sure that things happen. So that’s a great technique. And I’m happy to see the poll results reflect that.

Tracy, do you want to go over the rest of the poll results?

Tracy O’Rourke: The runner-up was fit in as my workload permits at 25% and almost the same percentage, 18, schedule an hour a day, 10% carve out a whole day every so often, and then there’s 4% that catch up on weekends.

So it’s a little concerning that people say, “Well, when my time permits. When my schedule permits, I’ll fit it in.” Because often, that means it’s not a high priority and that’s why sometimes projects take so long because we’re not actually making it a priority and fitting it in.

Elisabeth Swan: No.

Tracy O’Rourke: I really like it actually when you have these meetings that it’s not one way dialogue too. That it’s working meetings. You’re actually getting some work done as opposed to just having people give you updates. So those are a lot more fun too. It’s a great way to engage people. So hopefully when you’re having these meetings, you’re actually getting work done in the meetings not just checking on people.

Elisabeth Swan: Yeah. And as you just used the word, upping engagement, that’s always what you’re looking for with these projects. So you get a lot going on with just that one activity. So great results. Thanks everybody for chiming in on that poll.

Another issue we are aware of is that not everybody completes online training. It’s a great option but sometimes things get in the way. So we want to launch a poll to understand what are the challenges to completing online training and getting certification?

So here’s the next month’s poll:

What is your greatest challenge to completing online training and certification?

- A. Scheduling time on the calendar.

- B. Making it a priority.

- C. Staying interested in the material.

- D. Working on my own.

- E. Getting through difficult concepts.

So pick the greatest challenge for you and the poll is up now. So go ahead right on our website and enter your selection to the poll and we’ll report on it next month.

Tracy O’Rourke: Cool. I’m Tracy O’Rourke and you’re listening to the Just-In-Time Café Podcast. We’d love your feedback so please leave us a review on iTunes or on our website and don’t forget to subscribe.

Up next, it’s In the News.

In the News

Tracy O’Rourke: So Elisabeth, what’s going on in the Racine Unified School District?

Elisabeth Swan: This next news item comes to us from the Journal Times in Wisconsin and it’s written by Caitlin Sievers.

Kamaljit Jackson is Senior Accountability and Efficiency Officer at Racine Unified School District. And she has worked to ensure the whole school board went through White Belt Training, which is pretty big. And she just wanted to get the basic principles of Lean Six Sigma. And she is working to get improvement ideas from staff in all departments. She is asking teachers, janitors, secretaries, central staff members. She is doing a ton of outreach and making sure there’s a very high level of involvement.

The district already has used this practice to review their enrollment process and to develop changes in the middle school. So they’re already putting it into play. They are also using data from various student assessments to ensure classroom strategies are also effective. So they’re going right to a classroom level, which is great.

I just love hearing that process improvement is being applied to the educational system. We love to hear more from Kamaljit Jackson. Sounds like she is a mover and a shaker. We’ll have to reach out to her.

Tracy O’Rourke: Yes, bravo! Thank you for trying to make our educational systems better. I appreciate it being a mom.

Book Announcement

Elisabeth Swan: I’m Elisabeth Swan and you’re listening to the Just-In-Time Café Podcast. In a short while, we will get to Tracy’s interview with Danielle Hinz of King County, Washington. But first, we need to tell you about our new book!

Tracy O’Rourke: Yeah, we wrote a book!

Elisabeth Swan: We did! We’ve never done it before. And it took a while.

Tracy O’Rourke: It is a tool book. But it’s like no other tool book you’ve ever seen, not that we’re biased.

Elisabeth Swan: We got a lot of requests from people who use our online training as well as our listeners.

Tracy O’Rourke: And people just want a simple guidebook with a few basic tools, some instructions, some examples, and how about not boring. Super fun.

Elisabeth Swan: So, we created The Problem-Solver’s Toolkit: A Surprisingly Simple Guide to Your Lean Six Sigma Journey. We wrote it in a style of a road trip so there’s travel kits, instructions on how to avoid potholes as well as some sightseeing when you want to know more about a topic.

Tracy O’Rourke: And it includes some stuff at the Bahama Bistro just like the training. And they provide examples along the way. It’s full of infographics and lots of great visuals. And again, we built it to make it easy for everyone anywhere to build their solving-problem muscle and it’s fun. It’s like going out on a road trip but for your Lean Six Sigma journey. And I love road trips. How about you, Elisabeth?

Elisabeth Swan: I’m totally into road trips. We cover 35 basic tools and concepts to get you on your way. It’s an eBook. It’s free with Green or Black Belt Training.

Tracy O’Rourke: And you can also buy it for 29 bucks on our site and it’s available on Amazon too.

Elisabeth Swan: Did we mention we are really proud of it?

Tracy O’Rourke: We could always mention it again. And a big shout-out to Julius Pecson who partnered with us on the graphics and to Sion Lee who created the Bahama Bistro and all its inhabitants in the first place.

Elisabeth Swan: Tracy, we wrote a book! Coming up next, it’s Today’s Special. Tracy, give us a little preview of your interview with Danielle Hinz.

Tracy O’Rourke: So I’ve had the pleasure of working with Danielle Hinz and seeing her positive leadership impact and influence on her team. She is an exceptional leader and she has been trailblazer with combining leader standard work concepts and straight up leadership development for teams. That includes things like huddles, visual boards, A3 coaching, and she has been working Integris to spearhead leadership development and building cohesive teams.

And although she is leaving government and I know that they are sad to see her leave, her new role at Amazon will still be involving and making government better. I’m really excited to talk with her.

Today’s Special

Tracy O’Rourke: You’re listening to the Just-In-Time Café. I am Tracy O’Rourke. And joining me today is Danielle Hinz. Danielle’s role currently is the Chief Procurement Officer at King County. She is the Value Stream Manager for the $2 billion Procure to Pay Value Stream. And she has a staff of over 60 and they are serving the 13th largest county in the United States. Welcome, Danielle. How are you?

Danielle Hinz: I am wonderful. Thank you for having me.

Tracy O’Rourke: Well, let me tell you a little bit about Danielle. She has a master’s degree in Public Administration. She has been doing this work for 20 years plus in public procurement. And I have had the pleasure of working alongside of Danielle and I have observed that she is an excellent leader. People love her. She has a very forward-looking vision. She inspires others to act. She does not micromanage. And she also streamlines policies, implements better procedures, and overall reduces lead time in the Procure to Pay Value Stream for her customers.

Sadly though for King County and her staff, Danielle’s last day as Chief Procurement Officer is today. She is moving into a new role with Amazon because they are also in Seattle or Washington I should say.

So, what are you going to be doing there, Danielle?

Danielle Hinz: So, I will be going to Amazon Business as part of their government team and I will be working in their local government area. So it’s sort of a new role for them and for me. So I am excited to get started in that opportunity and see what that makes available to me but very sad to be leaving King County. It’s a wonderful organization and I think we’ve been doing a lot of great work here.

So I’ll definitely be keeping in touch to make sure that they continue on this direction forward and upward that they’ve been on here for several years.

Tracy O’Rourke: Yes. You are going to be very much missed I’m sure. And it’s nice that we see – I mean you are moving to a private sector but you’re still helping government. So in that way, that’s wonderful.

Danielle Hinz: Yeah. And I’ve committed my career to government procurement and feel very strongly about public service. And so, it was important to me that even in the new role, I will still be helping out with that same mission.

Tracy O’Rourke: Yes. Good. Very exciting. So people still – you’ll still be on the pulse of things and people could still reach out to you if they miss you and tell you how much they miss for at least two years.

Danielle Hinz: Absolutely yes.

Tracy O’Rourke: And I’m sure it will happen. OK. So what I’d love to talk with you about today is some of the significant impacts I’ve seen in working with you at Financial Business Operations Division in King County and sort of just your Lean journey and a little bit more about what your role in that journey has been as a leader.

So you came to FBOD from Colorado and started working there. And I would love to hear you talk a little bit about coming into this organization and they were just getting started with building their problem-solving culture. How did you feel about coming in with a program when you got started with FBOD?

Danielle Hinz: So coming in, I had a very small experience with Lean I would say. The organization where I come from in Colorado was trying to use those principles but not anywhere near to the extent that they were here in Finance and Business Operations.

So what I appreciated, there was a framework that was being provided for how we do process improvement and how we build employee engagement in our culture so that folks can really be inspired to focus on serving the customer in better ways and finding efficiencies in their process.

So what I appreciated, there was a framework that was being provided for how we do process improvement and how we build employee engagement in our culture so that folks can really be inspired to focus on serving the customer in better ways and finding efficiencies in their process. That sort of outcome has always been important to me and in procurement, that’s what we always get charged with from our customers is be faster in what you do and provide it to us for cheaper.

So we’re always trying to improve processes but what I appreciated about here like I say is that there was that framework of Lean to do that within. And that’s always great to have those tools and vernacular that folks can know what you’re talking about so that as they do improve their processes, they have some tools to do that.

Tracy O’Rourke: So you’re fairly new to some of this process improvement stuff is what you were saying.

Danielle Hinz: Yeah, certainly within the context of Lean. Yes.

Tracy O’Rourke: So what was it like coming in with this sort of mandate? Mandate I say because there’s always the hope that people are going to want to do it. What did you think? Were you’ve kind of taken aback? Were you excited? What was your feeling behind kind of getting started with something like that?

Danielle Hinz: For me, I was excited because like I say, I think having the structure in place to do process improvement and show successes in that area and be able to identify other room – other areas where there’s room for improvement is really good. And I’ve always appreciated being able to make stuff visible and the use of visual management, visual controls here in FBOD was already in place and lots of whiteboards on the wall and whatnot.

So the opportunity to be able to use that tool to figure out what’s going on and how we can make things better I think was very exciting to see that that stuff was already in existence and folks already sort of knew the philosophy was around it I guess even if they weren’t using it on a regular basis.

Tracy O’Rourke: So there were some tools and approaches that you’ve mentioned. Visual boards and problem boards and huddles and leader standard work, all of these things were things that FBOD implemented to start to build problem-solving muscles and develop a Lean culture. What did you think about those tools and those applications? Did you feel like some of them were more successful than others or did you have one that feel like worked really well?

Danielle Hinz: So I think they all have their place I guess is what I would say. And I think the challenge especially when I was newer to the organization was figuring out where the right place was to insert the different tools. When I came, folks have been trained on A3s and there was a lot of focus on determining what the problem statement was and getting that right and then looking into root causes and doing some analysis of the data and then socializing that with others who are involved in the process.

So folks are really trained on the A3 but kind of its use was sporadic I would say. And then we definitely had visual boards up. I think that they weren’t being used as a management tool to the extent that certainly they are today or that they were intended to be used. And I think – so we’ve really tried to figure out where is the place for those in process improvement.

And truly, I think that you throw a bunch of tools at people and they get a little overwhelmed with it. So kind of breaking it apart and saying, “OK, we’re going to focus on filling out a good A3 right now and then we’re going to go to the tier board and figure out how do we want to display the information and how do we want to then huddle around that information and on what frequency and kind of just coming up with a cadence of those things has been useful. And just starting at the beginning and working through it in terms of finding the problem.

I think problem boards for us were really useful because it gave people a place to post the problems that they saw in the work so that even if they couldn’t do anything at that time with that problem, at least it was somewhere in work that was getting to them.

I think problem boards for us were really useful because it gave people a place to post the problems that they saw in the work so that even if they couldn’t do anything at that time with that problem, at least it was somewhere in work that was getting to them. They could post that problem somewhere that was visible and they didn’t feel like it would get lost. So that helps kind of get the problem and then having folks being able to figure out how to write a good problem statement, who to involve in the socialization of a problem and determining what the root causes were. It’s very important.

And then I think being able to create some way of showing that on our tier boards and like I say, coming up with sort of a cadence of how frequently are we going to look at this information and then what are we going to do about it when we do look at it and have some conversations about it.

So I think all of these tools are useful but I think that you have to decide where to start and just start with a few tools and then build as you go because I think the other tools become more important as you move through the process.

Tracy O’Rourke: Yes. So of the five sections at FBOD, you guys were really the first group to decide that you’re going to have an established daily huddle in front of your board. So, how has that improved your team in general? So have you noticed how that has helped?

Danielle Hinz: Yes. We’ve been doing – our leadership team has been doing daily huddles now for probably close to a year. And I was really inspired to do this in going to a Lean tour Nordstrom’s. They have some of their teams that were doing daily huddles in front of a visual board. And I came back and wanted to try it because some of the problems they were using their board to solve were problems that I felt we had as well.

So primarily, it was that we and the leadership team rely on each other for a lot of different things including information that go back and forth between teams. And there were some gaps there in terms of folks getting information in a timely manner.

Folks also wanted to know what was going on in other areas especially as it may impact their own team and what was going on at any given day. So we started huddling like I say about a year ago. We designed a tier board that we huddle in front of every day that collects some of this information and tracks it. I think we’re on about version 5 on that board now, maybe even 6.

So it has definitely been evolving to meet the needs but it has really helped the information flow. Folks know who is waiting on them for what information and when it’s due by. We check it on that every day. So if there are questions about what the expectation is or when it’s needed or if there are hiccups and being able to pull something together. We’re able to address that on a daily basis instead of waiting until it’s due and then going, “Oh crap! I couldn’t get it because I didn’t understand what you were looking for or something like that.”

And people really quite honestly hate having their name on the board. Somebody is waiting on me. So people hate having their name on the board. And so, folks are getting stuff done ahead of deadlines and whatnot just so they can get their name off the board.

So yeah, it has been super effective and it also quite honestly, we do it first in the morning. So 8:00 o’clock every day we huddle and it’s a really good way just to start the day, get a temperature of where everybody is at, if there is something going on that somebody needs to address. We are able to do that first thing in the morning. So it has been really good for the whole team.

Tracy O’Rourke: So one thing I think leaders do struggle with, it’s something you mentioned that you have done successfully. You said you’re on version 6 or 5, one of the two.

Danielle Hinz: Yeah.

Tracy O’Rourke: And sometimes people just say, “We tried it. It didn’t work.” And they don’t do – my sense is that they’re not necessarily gathering feedback from the people that use the board. So tell us a little bit about how you were able to allow that to happen and promote that?

Danielle Hinz: Yeah. So when I came back from Nordstrom’s and threw the idea out, I sort of mocked something up on a tier board and said, “There are the problems that I’ve seen that I’m trying to address. Let’s get some feedback.”

And fortunately, I think we have a pretty high-performing team already so getting feedback is not usually a problem. So I mocked something up. We huddled at it one day. We talked about how we wanted to see and I sketched it out and we just started huddling there.

And quite honestly, after about a couple of weeks of doing that, it was obvious that we needed to already make some changes. So we made the changes. We raised what we had and put up something new. And now, we’ve done that a few more times.

And so, it is never that it didn’t work at the time that we started. It’s that our conversations evolved and we get a little bit better at one thing. And so maybe we don’t need to track that as much and so we realized we need to start tracking something different or in a different way. And so, we iterate the board so that we start capturing those things that are now important to us.

But yeah, our team, they don’t hesitate to give feedback. But I always allow the opportunity to folks feel like they’re more comfortable putting that on a sticky note and flapping it up there. And a little bit safer environment than let’s talk about how we want to change it. Not everyone is able to participate fully in a way like that. So always leaving room for put your stickies up on the board if you feel like there’s something up here you want to change or you want to talk about. So we do that too.

Tracy O’Rourke: That’s wonderful. So I always say that that’s sort of making a forum for extroverts to talk because the extroverts will tell you what they think. And I know who the extroverts are in your team. And then for the introverts who don’t really want to partake in that kind of engagement as much, they can put Post-Its. So it’s wonderful that you were able to channel that. So that I’m sure they appreciate.

So, I want to talk a little bit about some of the things that I know FBOD was doing that is sort of I guess it wouldn’t be the most common route for establishing a Lean culture, they spent a lot of time training and integrating what I would call soft skills and/or leadership training. Things like the 5 behaviors of a cohesive team, the leadership challenge. Both of those with Integris is I think the organization that was helping you with that.

And then also crucial conversations. So how do you feel about those pieces that were implemented to help build leadership and the problem-solving culture?

Danielle Hinz: So I think they’re absolutely critical to the success that we’ve had. And actually when I came in, sort of acknowledged that we had some more room to improve in terms of the culture that we had. And so, the leaders had gone through leadership challenge which I think brings again some shared vernacular and really helped to then kind of re-center yourself as a supervisor because when you’re in a management position but in a Lean culture, it’s really about coaching employees and enabling them to solve the problems that they find in their work. Whereas the typical role of a manager might be to just solve the problems that employees bring to us, and that’s what they expect and that’s what we think we’re expected to do.

And so, I think the leadership challenge was really critical in terms of shifting the thinking of our leaders about how we interact with our employees and kind of resetting the expectation almost of what our role is as it relates to problems that exist in our business processes.

So I think being able to have shared vernacular around we need to enable others to act, we need to be challenging the process because we’re modeling the way for our employees and we need to inspire that shared vision around where are we headed and why are we doing this anyway. And then of course just recognizing that in terms of encouraging the heart, the employees are people too and we need to make sure that we are paying attention to their personal needs as well. So I think it’s just – it’s critical to reset the expectation of what leader’s role is in a Lean environment.

And then in terms of the 5 behaviors of a cohesive team and crucial conversations, I just think it’s really important for – I’ve always been a fan of team building and I think there are different models out there. But I think these models have been really effective for our teams just to understand how it is that you can get to a really high-performing team in terms of having mutual respect, that conflict is good. You can have healthy conflicts.

And then giving folks the toolset of crucial conversations about how do you actually have healthy conflicts so that both parties walk away feeling like that was a productive experience rather than somebody going like, “Whew! I got that off my chest.” And the person is feeling a little beaten down in the process.

I think teaching folks how to do that was really important for us. And I think just for teams to understand that it’s those things that make us have really great results at the end has just been really useful. And our leadership team actually did our 2-year check-in on 5 behaviors of a cohesive team and we’re continuing to see improvement in how folks interact with each other.

And let’s face it. You’re going to have hiccups and conflicts in understanding what the role of that is and how we deliver results to our employees and our customers I think is really important to keep us focused on how important it is to engage productively in conflict and hash those things out with each other as they arrive.

Tracy O’Rourke: So they have the tools so when they do have conflict and I know that sometimes yeah, just like you said, sometimes managers shy away from conflict because they don’t necessarily know how to handle it or what to do. And having that productive conflict and challenging the process, those pieces I think – how do we make that better and how do we actually mind for that are very positive things that I think people avoid.

Danielle Hinz: Yeah. And I think just actually talking about how you’re supposed to be having conflict because I think sometimes we’re sort of trained to be nice. And so, people then think that if you are having conflict to someone that must mean you’re not doing what you’re supposed to be doing. But in actuality, talking about how there’s healthy conflict and that’s what we need to be having in order to make sure we’re really looking at an issue from all sides and taking into account everyone’s perspective to come up with the best result, I just think that’s really important to set that expectation.

Tracy O’Rourke: So your – I mean your group in particular, really embraced it and I want to believe it’s because you are a really good leader. You really embrace these tools. And ultimately, I think what’s interesting is your employee engagement scores have increased over the last couple of years too. So you guys doing employee engagement score and I also noticed that there was an – that was also increasing. Can you tell us a little bit about that?

Danielle Hinz: Yeah. So starting about three years ago, the county started doing annual employee engagement scores. And you are exactly right, over the 3-year course of those for Procurement and Payables, we have increased each year and we have continued to be on kind of a high end of the county quite honestly. We have a higher score than most other folks in the county and so does FBOD.

And so, I really do think it’s pointing at the Lean culture and the things that that needs to have in order to be successful, which is engaged employees, employees who feel like they can make a difference, and then having them actually make a difference.

So I think where we’ve seen success is by really encouraging employees to participate in process improvements that positively impact their work and then for them to see the results of that which if their own process is better, that’s awesome. But if their customer’s process is better, that’s even awesomer. And that’s what we’re really doing is we’re making our customer’s experience with our processes better and that is because our employees are embracing process improvement through Lean and figuring out ways to improve the customer’s experience.

And so, when they see that happening, I think they feel better about the work that they’re doing and feel supported by their leadership team and it just makes a much better overall environment for them to come to work in every day.

Tracy O’Rourke: Yes. So really, it’s a tremendous success story. So I’m really glad you are taking that time to speak with me and share your experiences with our audience because you have measurable success in terms of what you’re doing with Lean, how that is affecting your teams, the productivity, your employee engagement.

And those are very hard things to measure and the kind of improvements you’ve seen over the last three years are pretty significant. I can’t argue with that.

What advice do you have for leaders about being a better Lean leader?

Danielle Hinz: So I think just patience quite honestly and consistency and that you have to model the way. I think we have to take baby steps like I was saying earlier. I think start with a couple of the tools and get really good at those and then start figuring out how to make other tools work for you as the culture matures I guess in terms of how it’s using Lean. And you can introduce some other tools and folks can see the benefit of those.

And I think just being consistent in terms of the expectations for doing this work are not going to go away. What I heard when I came about three and a half years ago as a lot of folks saying, “We’re just going to wait it out. This is kind of the latest thing and this is going to go away eventually also so we don’t really have to embrace it.”

And I think just being consistent that no, this is really the way that you are expected to do this work now and giving them the room to do that, the folks who are saying they didn’t have the time to work on their process, so we gave them the ability to book time on their calendar to work on their processes instead of in their processes.

And so I think just sort of reiterating in every way that you can that this is important work and it’s here to stay is really important for employees to hear and to understand.

…supervisors taking on problems themselves and solving those problems, having conflict with others, healthy conflicts with others and it’s coming out with a good result at the end, and just supporting employees, all those things are critical to the success of a Lean culture.

And I think as leaders, we have to model the way. So I think the leadership team having tier bards that we interact with on a regular basis on supervisors taking on problems themselves and solving those problems, having conflict with others, healthy conflicts with others and it’s coming out with a good result at the end, and just supporting employees, all those things are critical to the success of a Lean culture.

And I think one thing that I did and I think is really important, when I came in, I met one-on-one with every employee just to get to know them a little bit and then I did my own process walks with employees so that I could see the way that they were working. And I think that for me, that really opened my eyes about how our folks are working because even though I’ve been in procurement for a long time, everyone’s process is slightly different.

And so seeing what that is with my own eyes really helped. And I think it just shows respect for the employees as well and give them the opportunity to show me the work that they do and just seeing how proud they are of how they serve our customers every day I think is – they want their management to understand that. And I think giving them the opportunity to do that has been very critical.

Tracy O’Rourke: Well, I think every leader should follow that advice if they don’t already. So that was wonderful. So setting expectations, modeling the way, showing respect for people, those are three really good insights.

And I really appreciate you coming to talk with us on the café today. Is there anything else you want to share with our audience?

This is how employees get inspired to come to work every day and show up with their best foot forward.

Danielle Hinz: No, I don’t think so except just I would just put in another plug. This is really important work. This is how employees get inspired to come to work every day and show up with their best foot forward. And so, it is really important. It just takes a while. You have to have patience because the culture especially in larger organizations just takes longer to shift.

But at the end of the day, employees really appreciate having a culture where they know their work is valued and that they are respected and that’s how they do their best every day. And when the time comes for them to leave the organization for whatever reason, they have really good things to say about having worked at the county. And I think that’s important too.

Tracy O’Rourke: So, you can find, if you want to ask Danielle more questions or pick her brain a little bit more because she is definitely a model leader, a great mentor for any female out there or male…

Danielle Hinz: Oh, thanks.

Tracy O’Rourke: …you can find her on LinkedIn, Danielle Hinz, that’s H-I-N-Z, Danielle with two L’s, right?

Danielle Hinz: Yup, yup.

Tracy O’Rourke: And we’ll look for you in Amazon as well. So thanks for coming to the café, Danielle.

Danielle Hinz: Yeah. Thanks for having me. It was fun.

Tracy O’Rourke: It was.

This Just In

Check out the latest success story webinar, Lesley Guertin of Cape Cod Child Care reduced classroom incidents by 50%. Another great example of using process improvement in education. And sign up for our next webinar: How Yellow Belts can Apply What They Learned in the Real World.

Elisabeth Swan: And join us for our next podcast episode where Tracy interviews the Vice-President of US Operations and Service at Taylormade Golf company, Kevin Limbach.

Tracy O’Rourke: Thanks for spending time with us at the Just-In-Time Cafe.

Elisabeth Swan: We’ll be back in two weeks!

Thanks for Listening!

Listen to more podcasts.

The post Podcast: Just-In-Time Cafe, Episode 32 – How Effective Lean Leaders Model the Way With Danielle Hinz appeared first on GoLeanSixSigma.com.

62 episodes

All episodes

×Welcome to Player FM!

Player FM is scanning the web for high-quality podcasts for you to enjoy right now. It's the best podcast app and works on Android, iPhone, and the web. Signup to sync subscriptions across devices.